2025 Top Trends in Calcium Silicate Board What You Need to Know

As we look ahead to 2025, the construction industry is poised for transformative changes, particularly in the realm of building materials. One such material that has garnered significant attention is Calcium Silicate Board. This innovative product not only offers remarkable fire resistance and thermal insulation but also contributes to sustainable building practices. According to Dr. Emily Johnson, a leading expert in construction materials, "The versatility and durability of Calcium Silicate Board will redefine industry standards in the coming years."

In this ever-evolving landscape, understanding the trends surrounding Calcium Silicate Board is crucial for architects, contractors, and builders alike. As functional and aesthetic demands increase, the emphasis on materials that enhance safety without compromising environmental integrity will be paramount. The insights gained from trends in Calcium Silicate Board will serve as a blueprint for those looking to stay ahead in a competitive market, ensuring that constructions meet modern-day challenges.

By delving into the top trends, this article aims to highlight the innovations and applications that make Calcium Silicate Board an essential component of future building projects. The exploration of these emerging trends will empower industry professionals to make informed decisions and adapt to the dynamic demands of the construction sector.

Key Characteristics of Calcium Silicate Board in 2025

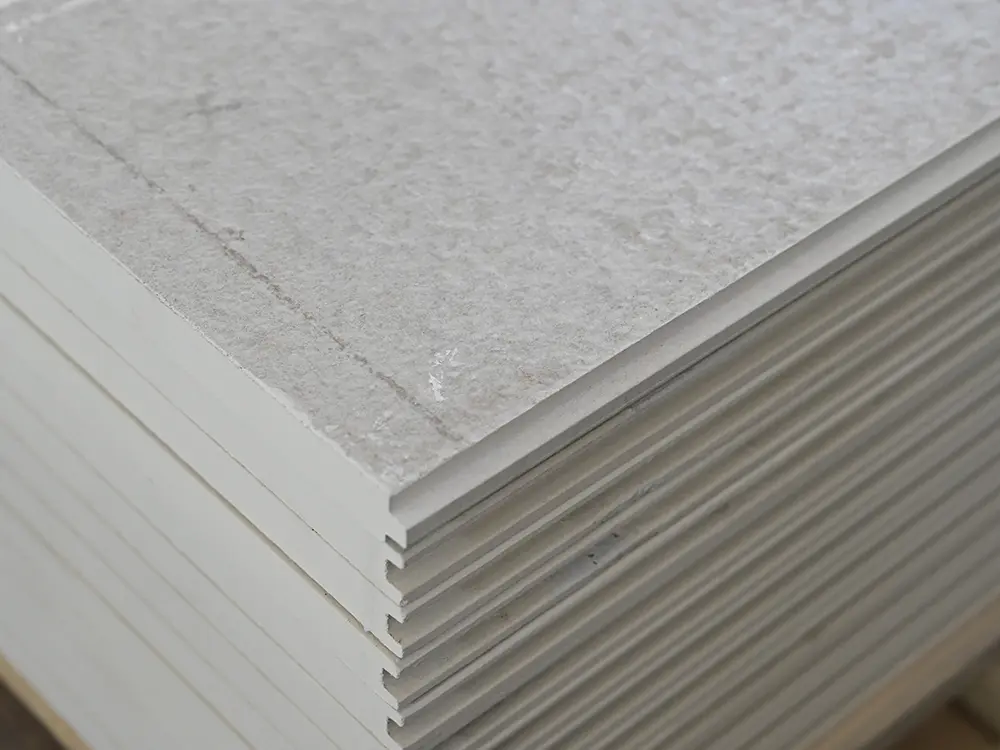

Calcium silicate boards have gained immense popularity in construction and insulation applications, and their key characteristics are set to evolve further by 2025. One of the most significant traits is their exceptional fire resistance. Made from a combination of silica and calcium compounds, they can withstand high temperatures, making them a preferred choice for building fire-rated walls and ceilings. Moreover, their lightweight nature coupled with excellent durability makes them easy to handle and install, reducing labor costs on construction sites.

Tip: When selecting calcium silicate boards, consider their density and thickness based on the intended application. Higher density boards provide better structural support and thermal insulation.

Another important characteristic is their moisture resistance. As building regulations evolve, the demand for materials that can withstand humidity and prevent mold growth will increase. Calcium silicate boards are resistant to moisture absorption, making them ideal for environments where moisture control is critical, such as kitchens and bathrooms.

Tip: Always ensure the edges of the boards are sealed during installation to enhance their moisture resistance and prolong the lifespan of your building elements.

Emerging Applications of Calcium Silicate Board in Construction

Calcium silicate board has emerged as a significant material in the construction industry, driven by its excellent properties such as fire resistance, thermal insulation, and acoustic performance. According to a report by Research and Markets, the global calcium silicate boards market is expected to grow at a CAGR of 5.4% from 2022 to 2027, reaching a valuation of approximately $4 billion by the end of the period. This growth is primarily fueled by the increasing demand for sustainable building materials and the rising awareness of fire safety protocols in various construction projects.

In terms of emerging applications, calcium silicate boards are being increasingly utilized in high-rise buildings, as they provide essential fire protection ratings without compromising structural integrity. The boards are also gaining popularity in green building initiatives, where their eco-friendly composition contributes to earning LEED certification. Additionally, advancements in manufacturing technology have led to the introduction of customized solutions, enhancing their applicability in diverse environments, such as industrial facilities and residential settings. The versatility and durability of calcium silicate boards make them an invaluable asset for modern construction projects aimed at improving safety and sustainability.

Sustainability Trends Influencing Calcium Silicate Board Production

The production of calcium silicate boards is increasingly influenced by sustainability trends that are shaping the building materials industry. According to a report by ResearchAndMarkets, the global demand for eco-friendly construction materials is projected to grow at a CAGR of 8.3% from 2021 to 2026. This shift is evident in the growing preference for calcium silicate boards, which are renowned for their fire resistance, durability, and low environmental impact. These boards are primarily made from natural and recycled materials, aligning perfectly with the sustainability ethos.

Moreover, manufacturers are adopting green practices in the production of calcium silicate boards, emphasizing energy-efficient processes and the use of renewable energy sources. A survey by Smithers shows that 62% of industry professionals believe the adoption of sustainable practices will lead to significant cost savings in the long run. As companies innovate to reduce waste and lower carbon emissions, the calcium silicate board market is expected to thrive within the green construction movement, paving the way for a more sustainable future in building materials.

Technological Innovations Enhancing Calcium Silicate Board Performance

Technological innovations in the calcium silicate board industry are shaping its future by significantly enhancing performance characteristics. Advances in manufacturing processes have resulted in products that exhibit improved thermal insulation, fire resistance, and durability. These enhancements are critical, particularly in industries such as petrochemicals, where high-temperature applications require materials that can withstand extreme conditions without compromising structural integrity.

Moreover, ongoing research and development focus on incorporating sustainable practices into the production of calcium silicate boards. By utilizing eco-friendly materials and energy-efficient techniques, manufacturers are not only minimizing their environmental impact but also meeting the growing demand for sustainable construction solutions. This trend aligns with a broader shift toward green building practices, which increasingly prioritize material performance alongside sustainability, setting the stage for a more resilient built environment.

Regulatory Changes Impacting the Calcium Silicate Board Industry in 2025

In 2025, the calcium silicate board industry will face significant regulatory changes that will reshape market dynamics and product standards. Governments worldwide are tightening building regulations to enhance fire safety and improve energy efficiency. According to the Global Calcium Silicate Board Market Report 2023, approximately 65% of industry players will need to comply with new certifications and standards related to fire resistance and environmental impact, significantly affecting production processes and material sourcing.

As the demand for sustainable building materials rises, companies must adapt to initiatives promoting eco-friendly practices. For instance, the new regulations may introduce stricter guidelines on sourcing raw materials, pushing manufacturers toward more sustainable options. By 2025, it is projected that over 40% of calcium silicate boards will need to be produced using recycled materials or those sourced from renewable resources.

**Tips:** To stay ahead in this evolving landscape, manufacturers should invest in R&D to innovate compliant products and enhance their supply chain transparency. Engaging with regulatory bodies early can also offer insights into upcoming changes, helping companies adjust their strategies proactively. Networking at industry conferences can provide invaluable knowledge about best practices in navigating these regulatory shifts.

2025 Top Trends in Calcium Silicate Board

This chart illustrates the top trends in the calcium silicate board industry for 2025, highlighting the percentage of industry focus on various aspects such as sustainability, fire resistance, moisture resistance, lightweight properties, and cost-effectiveness.

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

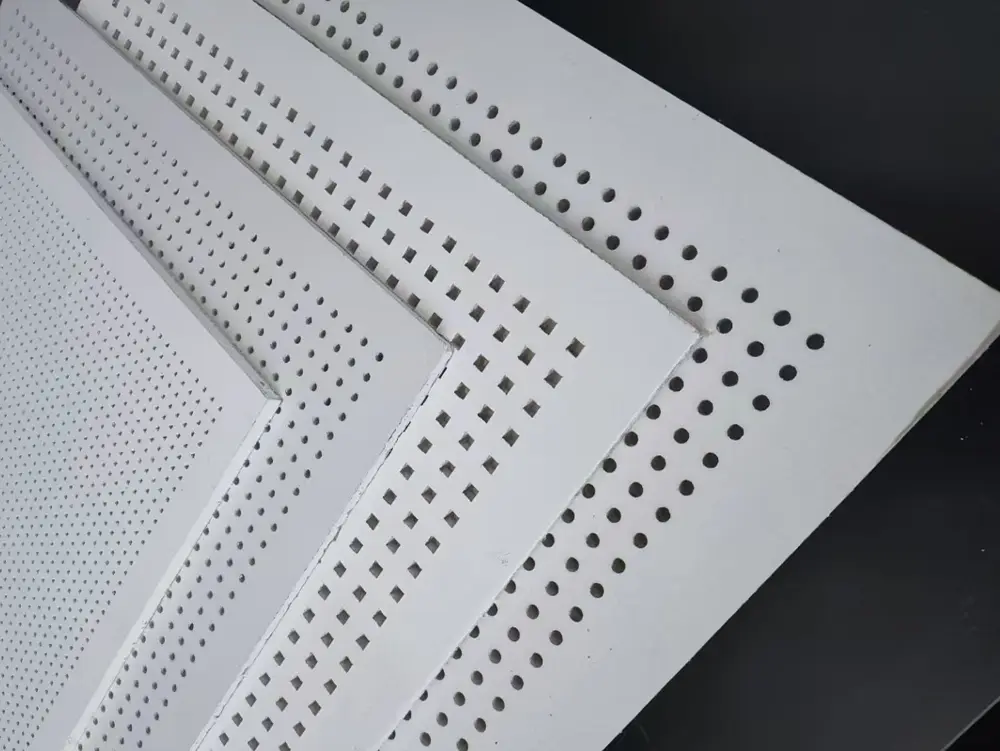

LEAO®Deco Ceiling LEAO® Perforated Ceiling

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel