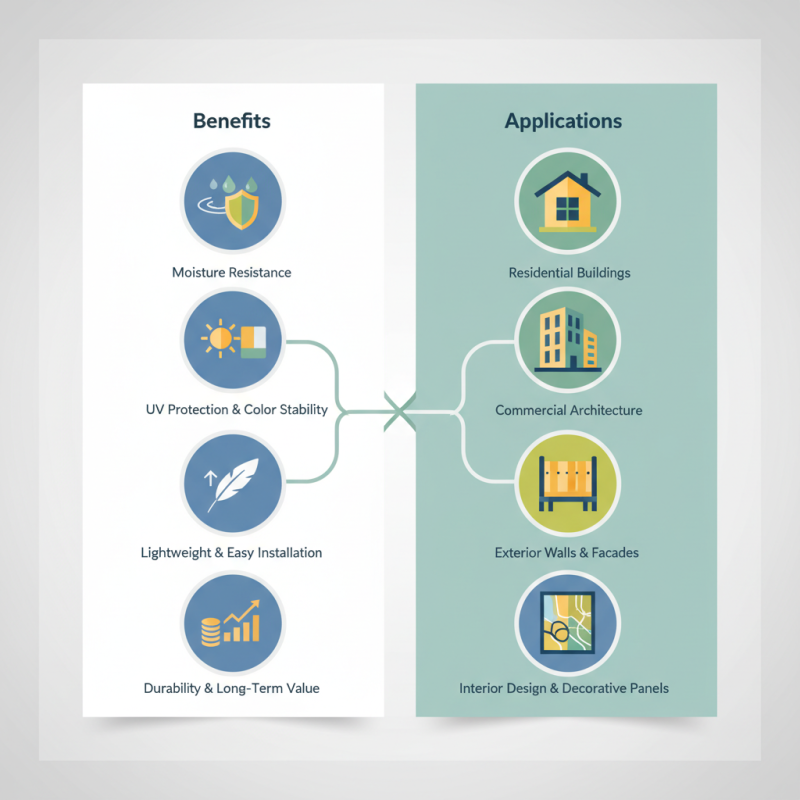

2026 Top Uv Coated Fiber Cement Board Benefits and Applications?

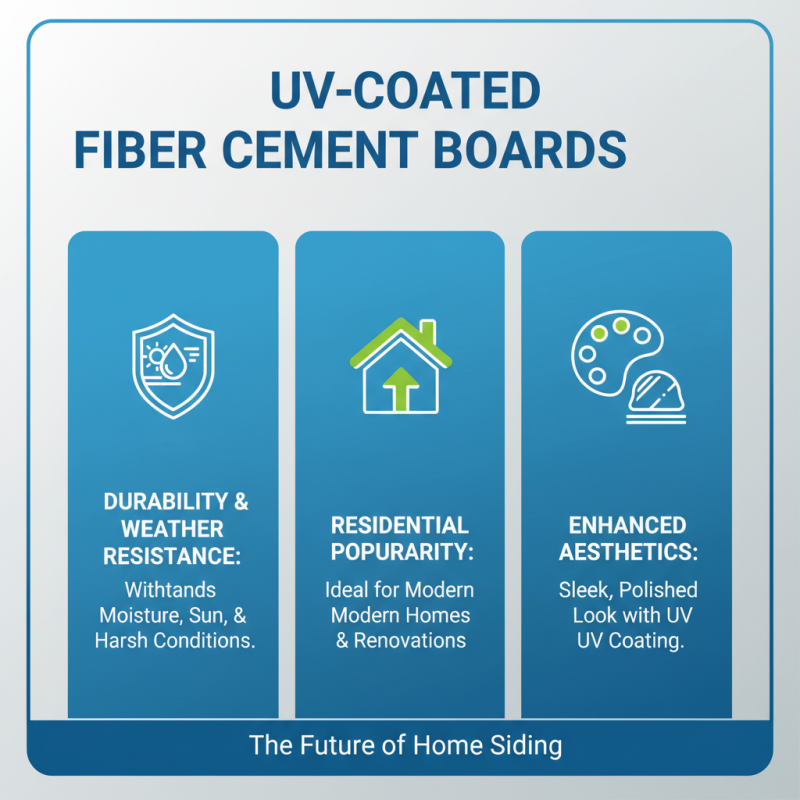

In recent years, the construction industry has seen a significant shift toward innovative materials. One such material gaining attention is the UV Coated Fiber Cement Board. This product combines durability, aesthetics, and functionality. It offers a range of benefits for various applications, making it a popular choice for builders and architects alike.

The UV Coated Fiber Cement Board is not only resistant to moisture but also withstands harsh environmental conditions. Its surface coating provides enhanced UV protection, which helps maintain vibrant colors over time. This feature is crucial for projects in sunny regions. Additionally, the material is lightweight, making installation easier and more efficient.

However, while the UV Coated Fiber Cement Board is praised for its advantages, there are also challenges to consider. For example, the initial cost may be higher than traditional materials. Builders must weigh these factors carefully. The decision to use such boards should involve a thorough evaluation of long-term benefits versus short-term costs.

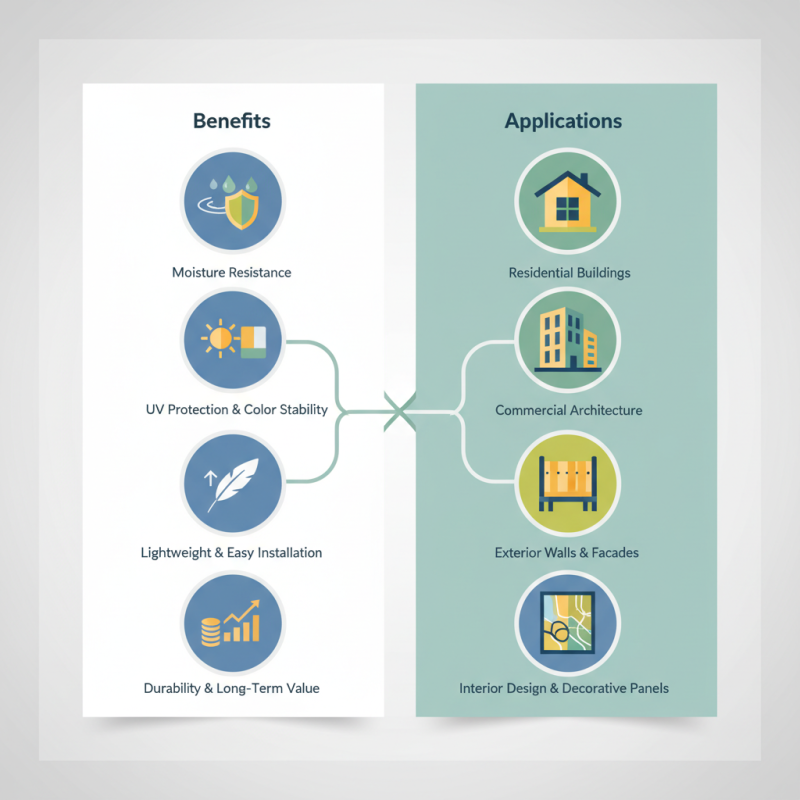

Advantages of UV Coated Fiber Cement Board in Construction Industry

UV coated fiber cement boards are becoming popular in the construction industry. They offer numerous advantages that make them a preferred choice for builders and architects. One of the most significant benefits is their enhanced durability. The UV coating protects the boards from harsh weather, reducing wear and tear. This makes them ideal for exterior applications. Their longevity can lower maintenance costs, which is a major concern for many construction projects.

Another key advantage is their aesthetic appeal. The UV coating allows for vibrant colors and finishes. This can elevate the visual quality of buildings, making them stand out. Easy installation adds to their attractiveness. However, it’s important to ensure proper training for installers. Inadequate installation can lead to issues down the line. This is crucial for maintaining the benefits of the product and achieving desired outcomes.

While UV coated fiber cement boards show great promise, potential drawbacks exist. A small percentage may experience coating wear over time. This can vary based on environmental factors. Regular inspections are necessary to address any vulnerabilities. Awareness about these issues fosters informed decision-making. It encourages a more responsible approach in utilizing these materials in construction projects.

Applications of UV Coated Fiber Cement Boards in Residential Projects

UV coated fiber cement boards are gaining popularity in residential projects due to their unique properties. These boards are durable and resistant to weather elements. They can withstand moisture, sun exposure, and harsh conditions. Additionally, their UV coating enhances their appearance, providing a sleek and polished look.

When used for siding or cladding, they offer high customization options. Homeowners can choose various colors and textures. This versatility allows for creative architectural designs. However, choosing the right design can be challenging. Consider how each color interacts with natural light. It can significantly affect your home’s overall aesthetic.

**Tips:** Always sample colors before committing. This helps in visualizing how it will look on your home. Regular maintenance is key. While the UV coating protects, no surface is entirely immune to wear over time. Pay attention to local climate conditions when selecting materials.

One challenge is installation. Working with fiber cement can be complicated. Proper tools and techniques are essential for a successful application. Errors during installation may lead to water damage or reduced durability. It's crucial to consult professionals with experience. They can guide you in making the right choices for your home.

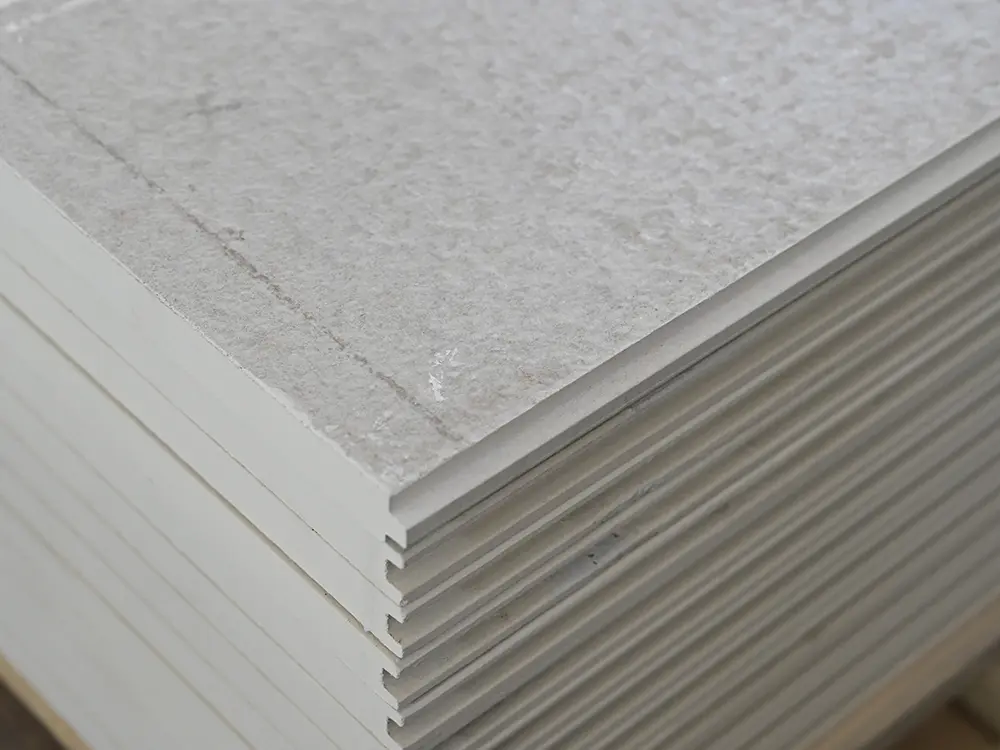

Impact of UV Coating on Durability and Longevity of Fiber Cement Boards

UV coating significantly enhances the durability of fiber cement boards. This technology helps create a protective layer that withstands environmental stresses. Reports show that UV-coated boards can resist fading and degradation for over 20 years. This longevity is crucial in various applications, particularly in building facades and roofing materials.

The enhanced resistance offered by UV coatings also reduces maintenance costs. According to industry data, property managers save up to 30% on maintenance with UV-coated products. However, not all UV coatings perform equally. Some lesser-known brands may lack the necessary durability, leading to potential failures. Testing is vital to ensure quality.

Further, the impact of UV coatings extends to environmental conditions. They provide protection against moisture, UV radiation, and temperature fluctuations. Studies indicate that fiber cement boards with UV coatings experience 50% less water absorption. Yet, challenges remain in achieving uniform application and thickness. Proper installation is essential to maximize performance and lifespan.

Market Trends: Growth of UV Coated Fiber Cement Boards by 2026

The market for UV coated fiber cement boards is rapidly evolving, driven by their versatility and durability. Reports indicate that the global fiber cement board market could reach $10 billion by 2026, with UV coated variants making a significant impact. The growing demand for sustainable building materials has pushed innovations in this sector. UV coatings offer enhanced resistance to weathering, UV degradation, and even microbial growth. This paints a promising future for fiber cement boards in various applications.

Construction trends highlight a shift toward eco-friendly materials. UV coated fiber cement boards are seen as ideal for residential and commercial buildings. Their lightweight nature and superior aesthetics appeal to architects and contractors alike. Additionally, the ease of installation adds to their attractiveness. However, the market still faces challenges. Quality control and inconsistency in production methods can hinder growth.

Market analysts expect a CAGR of around 7% from 2021 to 2026 for UV coated fiber cement boards. This expansion reflects a broader awareness of environmental impact and energy efficiency in construction. Nonetheless, the industry must address these production discrepancies to sustain growth. It's vital for stakeholders to remain vigilant in quality and innovation.

Growth of UV Coated Fiber Cement Boards by 2026

Cost-Effectiveness of UV Coated Fiber Cement Boards Compared to Alternatives

When considering the cost-effectiveness of UV coated fiber cement boards, several factors come into play. These boards offer impressive durability, resisting moisture and insect damage. This durability can lead to cost savings in long-term maintenance. Installation costs may be higher initially, but the reduced need for repairs often offsets this.

UV coated fiber cement boards are also energy-efficient. They help maintain consistent indoor temperatures, lowering heating and cooling bills. Compared to traditional materials, their lifespan is significantly longer, which means fewer replacements over time. However, it’s essential to evaluate your specific project needs. Not all applications may justify the upfront investment.

Another factor to consider is aesthetic appeal. UV coatings can enhance the board's appearance, making it attractive for various design projects. While the initial cost may seem daunting, the value it adds is considerable. Still, some might argue about the durability of the coating over time. It's worth reassessing expectations and longevity under certain weather conditions.

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

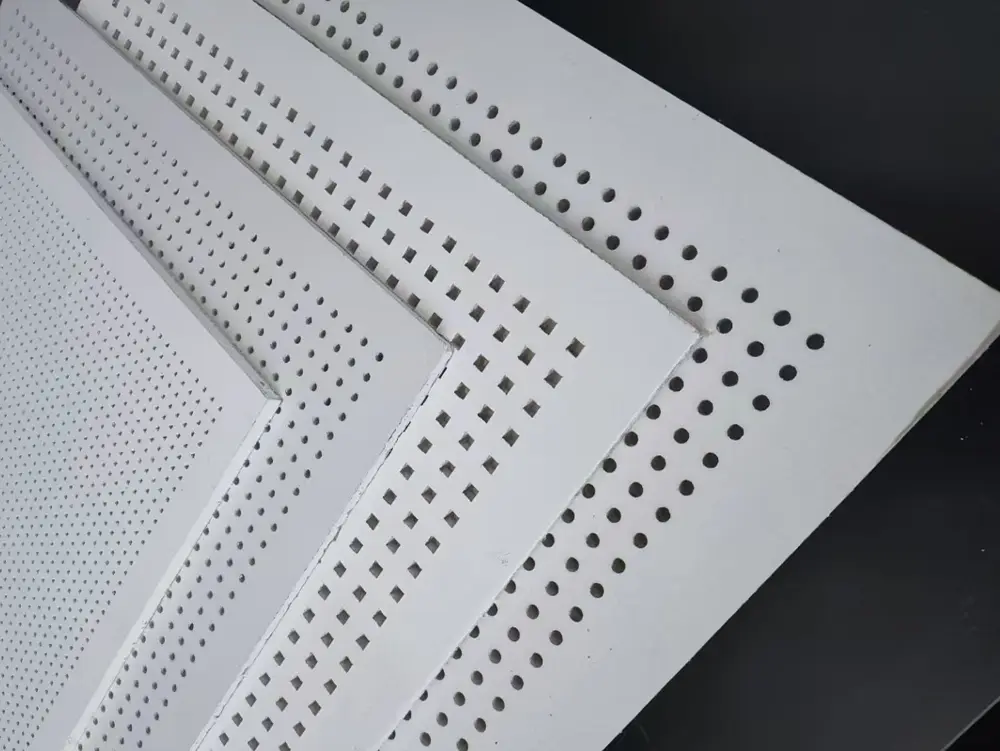

LEAO®Deco Ceiling LEAO® Perforated Ceiling

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel