Top Benefits of Fiber Cement Partition Boards for Your Next Construction Project

In the ever-evolving realm of construction materials, Fiber Cement Partition Boards have emerged as a game-changer, revolutionizing the way we approach interior and exterior spaces. These boards are composed of a unique blend of cellulose fibers, cement, and sand, resulting in a product that combines the strength and durability of cement with the lightweight and versatility reminiscent of traditional drywall. As construction projects increasingly prioritize sustainability, efficiency, and performance, the advantages of incorporating fiber cement partition boards become increasingly evident.

The use of Fiber Cement Partition Boards can significantly enhance the durability and longevity of structures. Their resistance to moisture, warping, and pest damage makes them an ideal choice for various environments, especially in areas prone to humidity. Additionally, these boards offer excellent sound insulation properties, making them perfect for residential and commercial applications alike. This introduction highlights not just the practical benefits but also the myriad possibilities that come with the adoption of fiber cement partition boards in construction ventures, paving the way for innovative design and functionality in modern architecture. Embracing this material can lead to greater efficiency during construction, reducing time and labor costs while ensuring a high-quality finish that stands the test of time.

Top Benefits of Fiber Cement Partition Boards for Your Next Construction Project

Fiber cement partition boards have gained immense popularity in construction projects due to their numerous advantages over traditional materials. One of the standout benefits is their durability. According to a 2022 report from the National Association of Home Builders, fiber cement boards can withstand extreme weather conditions, including heavy rains and strong winds, making them an ideal choice for both residential and commercial spaces. Additionally, these boards are resistant to rot, termites, and fire, providing peace of mind to builders and homeowners alike.

Another significant advantage is the thermal efficiency that fiber cement partition boards bring to a building. A study by the American Council for an Energy-Efficient Economy indicated that buildings utilizing fiber cement materials can achieve up to 25% better energy efficiency compared to those constructed with traditional drywall. This leads to lower energy costs and a reduced carbon footprint over the life of the building.

Tips: When incorporating fiber cement partition boards into your next project, ensure proper installation to maximize their benefits. Additionally, consider using acoustically-rated boards in spaces where sound insulation is a priority, such as offices or educational facilities. Finally, invest in high-quality finishing materials to complement the aesthetic appeal of fiber cement while maintaining its functional advantages.

Understanding Fiber Cement: Composition and Manufacturing Process

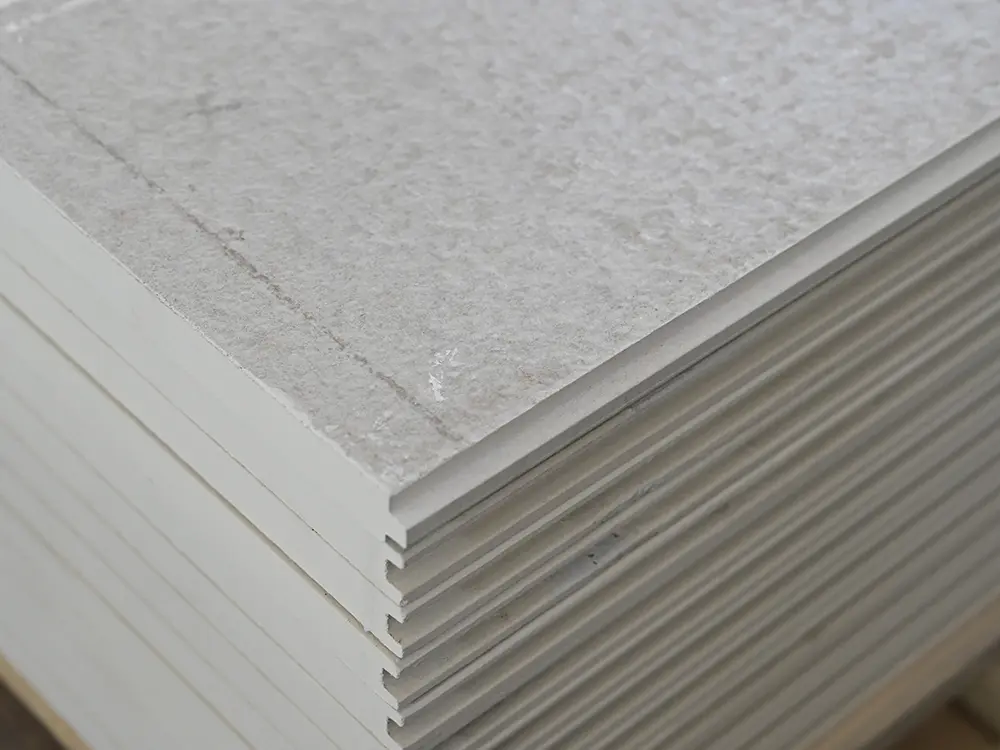

Fiber cement boards are a versatile building material that has gained popularity in the construction industry due to their durability and adaptability. Understanding their composition and manufacturing process is crucial for appreciating their benefits. Fiber cement is typically made from a mixture of cement, sand, and cellulose fibers, which are sourced from wood pulp. This combination not only enhances structural integrity but also improves the board's resistance to moisture, fire, and pests, making it an excellent choice for various applications.

The manufacturing process begins with the precise blending of these raw materials, followed by the addition of water to form a slurry. This slurry is then compressed and shaped into boards under high pressure. The boards undergo a curing process, where they are subjected to steam, which helps in the chemical reaction that strengthens the materials. The result is a robust and lightweight product that can be easily cut and installed. The durability and eco-friendly nature of fiber cement boards, stemming from their natural components, make them a reliable option for a wide range of construction projects, from residential homes to commercial buildings.

Durability and Longevity: Fiber Cement Partition Boards in Construction

Fiber cement partition boards have gained significant popularity in the construction industry due to their impressive durability and longevity. According to a report by Global Market Insights, the fiber cement market is anticipated to surpass $30 billion by 2026, primarily driven by the increasing demand for resilient building materials. Unlike traditional materials, fiber cement boards are resistant to moisture, fire, and pests, making them particularly suitable for a variety of environments. Their ability to withstand extreme weather conditions without warping or deteriorating contributes to their extended lifespan, often exceeding 50 years under typical conditions.

The longevity of fiber cement partition boards is closely tied to their composition, which includes cellulose fibers, cement, and sand. This blend not only enhances their structural integrity but also minimizes maintenance needs over time. A study from the National Association of Home Builders indicates that buildings constructed with fiber cement materials achieve lower life-cycle costs due to reduced repair and replacement frequencies. Consequently, using fiber cement boards can lead to substantial long-term savings for construction projects, reinforcing their appeal for builders and architects prioritizing sustainability and efficiency in their designs.

Cost-Effectiveness: Savings with Fiber Cement Over Traditional Materials

Fiber cement partition boards have gained popularity in construction projects due to their impressive cost-effectiveness when compared to traditional materials. One of the most significant advantages is the reduced long-term expenses associated with maintenance and durability. Fiber cement is resistant to moisture, termites, and fire, which translates to lower repair costs and longer service life. This resilience ensures that any initial investment in fiber cement boards pays off over time, making them a smart choice for budget-conscious builders.

Tips for maximizing savings with fiber cement include purchasing in bulk to take advantage of wholesale prices. Additionally, integrating these boards into your design early in the planning phase can help in estimating the overall construction costs more accurately, avoiding unexpected expenses later on. Don't forget to consider the installation process; fiber cement boards can often be installed more quickly than traditional materials, further cutting down labor costs.

Furthermore, fiber cement’s versatility allows it to be utilized in various applications throughout a project, reducing the need for multiple materials. This not only simplifies the logistics of procurement but also makes it easier to keep the project within the budget while maintaining quality and durability. Choosing fiber cement for your next construction project can lead to significant financial benefits and streamline the entire building process.

Cost-Effectiveness of Fiber Cement Partition Boards vs Traditional Materials

This chart illustrates the average cost per square foot for different partition board materials. As shown, Fiber Cement offers the most cost-effective solution for construction projects, significantly reducing material costs compared to traditional alternatives like gypsum board, wood, and metal.

Fire Resistance and Safety Standards of Fiber Cement Boards

Fiber cement partition boards have gained significant popularity in construction due to their remarkable fire resistance and adherence to safety standards. One of the primary advantages of these boards is their ability to withstand high temperatures without compromising structural integrity. When subjected to fire exposure, fiber cement boards do not emit toxic fumes, making them a safer option for both residential and commercial applications. This feature is particularly crucial in areas where fire safety regulations are stringent, ensuring that these materials help to create safer environments for occupants.

In addition to their fire-resistant properties, fiber cement boards meet various international safety standards, which enhances their appeal to builders and architects. They are tested and certified against fire hazards, providing peace of mind that they can help prevent the rapid spread of flames during emergencies. The robust composition of fiber cement contributes to its durability, allowing it to serve effectively as a fire barrier in critical spaces such as walls, ceilings, and partitions. As a result, integrating fiber cement boards into construction projects not only promotes safety and compliance with regulations but also underscores a commitment to using materials that prioritize human safety in building design.

Conclusion

Fiber Cement Partition Boards offer a multitude of benefits that make them an excellent choice for construction projects. Comprised of a blend of cellulose fibers, cement, and other materials, these boards undergo a rigorous manufacturing process that enhances their durability and longevity. They withstand harsh environmental conditions, making them a reliable option for both interior and exterior applications.

In addition to their strength, Fiber Cement Partition Boards are cost-effective, providing significant savings compared to traditional materials. Their fire resistance and compliance with safety standards further elevate their appeal for construction safety. Moreover, the environmental impact of these boards is minimal, as they are made from sustainable materials, contributing to greener building practices. Overall, Fiber Cement Partition Boards are an outstanding solution for modern construction needs, blending performance with ecological responsibility.

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

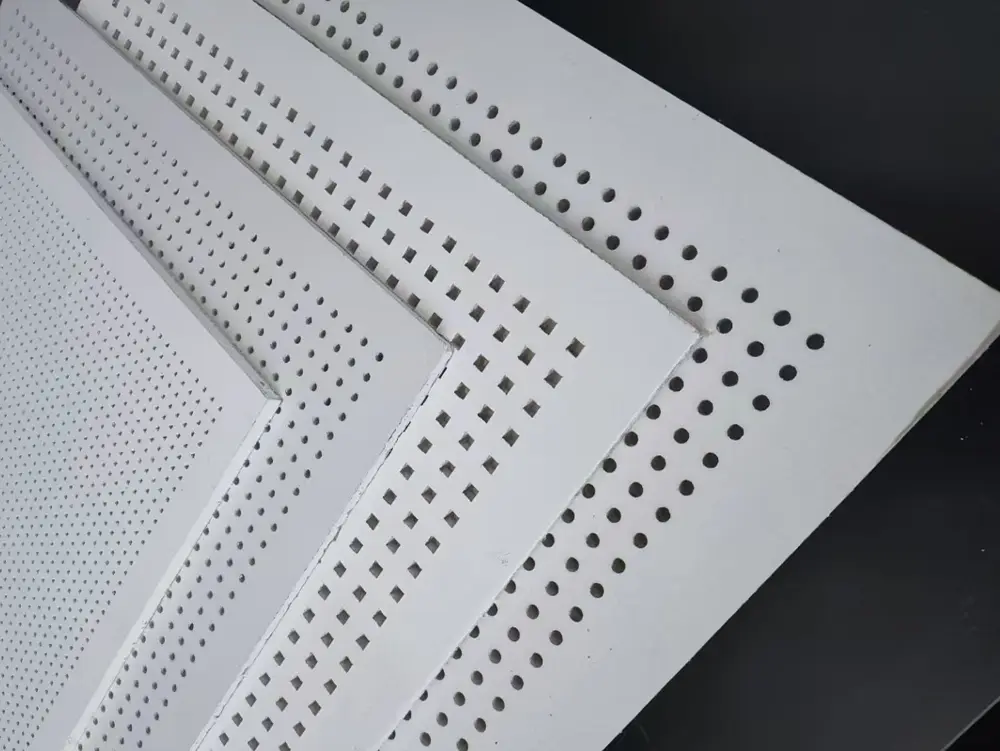

LEAO®Deco Ceiling LEAO® Perforated Ceiling

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel