Why Choose Fiber Cement Formwork Boards for Your Construction Needs?

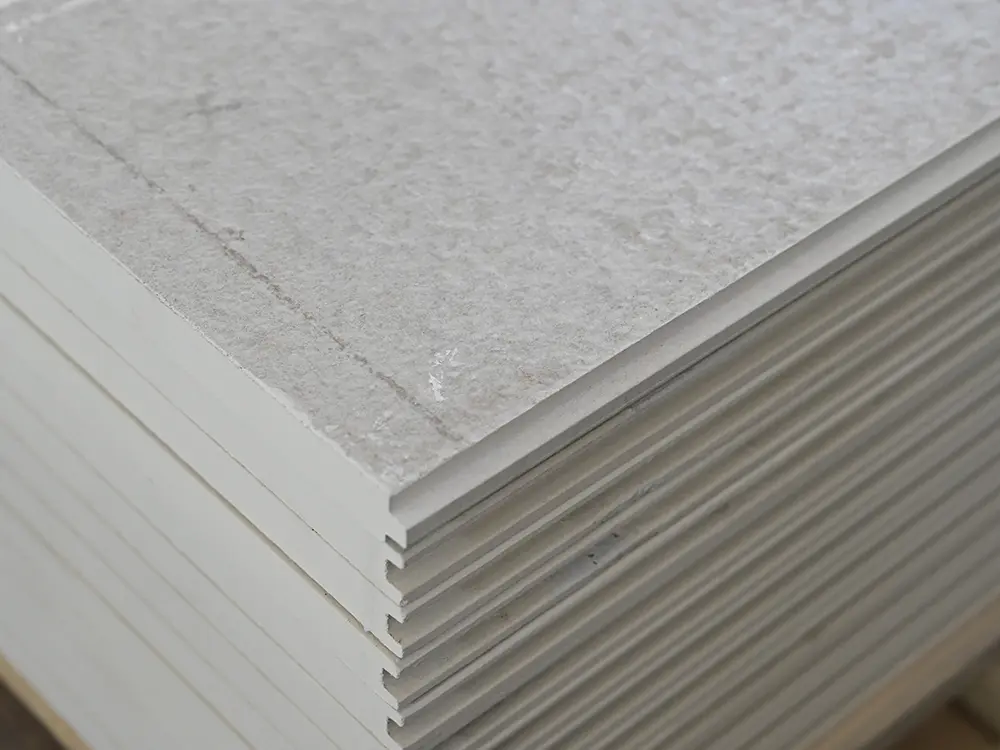

In the construction industry, selecting the right materials is crucial for ensuring efficiency, durability, and cost-effectiveness. Among the various options available, Fiber Cement Formwork Boards have emerged as a preferred choice for many builders and contractors. This innovative material combines the strength of cement with the fibrous properties of cellulose, resulting in a lightweight yet robust formwork solution. By choosing Fiber Cement Formwork Boards, construction professionals can benefit from enhanced structural integrity and a longer lifespan compared to traditional formwork materials.

Moreover, Fiber Cement Formwork Boards offer significant advantages in terms of versatility and ease of use. They can be molded into various shapes and sizes, accommodating diverse construction requirements. The boards also exhibit excellent resistance to moisture, fire, and pests, making them a reliable choice for both interior and exterior applications. Given the increasing demand for sustainable construction practices, using Fiber Cement Formwork Boards aligns with eco-friendly initiatives, as they are often made from recycled materials and have lower environmental impacts.

As the construction landscape evolves, adopting advanced materials like Fiber Cement Formwork Boards can lead to improved project outcomes, reduced labor costs, and greater overall efficiency. This article will explore the numerous benefits of utilizing Fiber Cement Formwork Boards, providing valuable insights for professionals seeking to enhance their construction processes.

Benefits of Fiber Cement Formwork Boards in Construction Projects

Fiber cement formwork boards have emerged as a pivotal choice for construction projects due to their unmatched benefits. One significant advantage is their durability, as they are resistant to weather, pests, and fire, making them suitable for various climates and conditions. According to recent studies, incorporating fiber cement in construction can improve the lifespan of structures by up to 30%. This extraordinary longevity reduces the need for frequent repairs and replacements, which is crucial for long-term cost savings.

Moreover, fiber cement formwork boards provide excellent thermal and acoustic insulation properties. Research indicates that buildings utilizing these materials can achieve up to 20% better energy efficiency compared to traditional methods. This not only contributes to lower energy consumption but also enhances occupant comfort. Additionally, the versatility of fiber cement allows architects to explore innovative designs without compromising structural integrity, as demonstrated in recent projects like the Elverby Primary School, where such materials were pivotal to the aesthetic and functional aspects of the design. Implementing fiber cement in construction is not just a trend; it's a strategic response to modern building challenges.

Durability and Weather Resistance of Fiber Cement Materials

Fiber cement formwork boards have become a popular choice in construction due to their exceptional durability and weather resistance. Engineered to withstand various environmental conditions, these boards offer a reliable solution that can endure rain, wind, and UV exposure without losing structural integrity. This resilience ensures that your projects can continue on schedule, even in adverse weather, reducing the risks of delays caused by material failures.

When considering fiber cement boards for your next project, it is essential to keep a few tips in mind. First, ensure proper installation by using suitable tools and techniques to maximize the boards’ lifespan. Second, always check for the manufacturer's specifications regarding maintenance and upkeep, as this can help maintain their weatherproof qualities over time. Lastly, consider the specific environmental conditions of your construction site; selecting the right type of fiber cement board for your local climate can further enhance performance and durability.

Choosing fiber cement formwork boards not only assures lasting quality but also promotes sustainability in construction. Their resistance to moisture and pests means fewer replacements and repairs are necessary, contributing to a more eco-friendly building practice.

Cost-Effectiveness of Using Fiber Cement Formwork Boards

Fiber cement formwork boards have emerged as a cost-effective solution for construction needs, particularly in light of rising material prices and housing costs. Their durability and resistance to moisture, fire, and pests make them an attractive alternative to traditional formwork, which can often lead to higher expenses both in materials and labor. The ability to reuse fiber cement boards across multiple projects significantly enhances their value proposition, lowering overall construction costs while maintaining structural integrity.

Moreover, the incorporation of fiber cement boards aligns with ongoing trends toward sustainable building practices. As the industry shifts focus toward environmentally friendly materials, these boards offer a reliable option that minimizes waste and supports green building initiatives. By investing in fiber cement formwork boards, construction businesses can not only achieve cost savings but also position themselves favorably in an increasingly competitive market that emphasizes sustainability and cost efficiency.

Environmental Impact and Sustainability of Fiber Cement Products

Fiber cement formwork boards are increasingly recognized for their environmentally friendly properties and sustainability in the construction sector. These materials are composed of natural and recycled components, ensuring a lower environmental footprint throughout their lifecycle. Studies have shown that high-performance cementitious composites, which incorporate construction and industrial waste, help address the pressing demand for eco-friendly materials. This innovative approach not only reduces waste but also enhances the overall performance of construction products, aligning with evolving environmental regulations and consumer preferences.

When considering materials for your next construction project, opt for fiber cement boards due to their durability and sustainability. These boards can significantly minimize the ecological impact through efficient use of resources.

**Tip:** Always look for products with certifications that indicate sustainability practices, such as Cradle to Cradle certification. This can help ensure that you are making a responsible choice that supports circular economy principles.

Moreover, advancements in utilizing agricultural by-products and mine tailings in building materials further bolster the sustainability agenda, making fiber cement an excellent choice for environmentally conscious builders.

**Tip:** Regularly check for updated sustainability reports from manufacturers to stay informed about their practices and progress in reducing their environmental impact.

Why Choose Fiber Cement Formwork Boards for Your Construction Needs? - Environmental Impact and Sustainability of Fiber Cement Products

| Aspect |

Fiber Cement |

Traditional Materials |

| Material Composition |

Cement, Sand, Cellulose Fiber |

Wood, Steel, Concrete |

| Recyclability |

High |

Varies (Low for Wood) |

| Durability |

Weather Resistant, Long-lasting |

Subject to Rot/Corrosion |

| Environmental Impact |

Lower CO2 Emissions during Production |

Higher CO2 Emissions |

| Cost Efficiency |

Cost-effective for Long-term Use |

High Maintenance and Replacement Costs |

Applications and Versatility of Fiber Cement in Various Construction Types

Fiber cement formwork boards offer exceptional versatility for a wide range of construction applications. These boards are ideal for various building types, from residential homes to commercial projects. Their durability and resistance to moisture make them suitable for both exterior and interior use, allowing builders to create resilient structures that withstand environmental stresses. Moreover, fiber cement boards can be easily cut and shaped, providing flexibility in design and making them an excellent choice for unique architectural features.

When using fiber cement formwork boards, it's essential to consider a few tips. First, ensure proper installation to maximize their performance. This includes using appropriate fasteners and ensuring that joints are sealed correctly to prevent water ingress. Second, always follow safety protocols during handling, as the dust generated during cutting can be hazardous. Lastly, take advantage of the boards' versatility by experimenting with different finishes—whether painted or natural—to achieve the desired aesthetic for your project.

The applications of fiber cement in construction are extensive. From wall cladding and roofing to flooring and even as partitions, these boards serve multiple purposes. Their fire-resistant properties make them particularly valuable in commercial construction, where safety regulations are stringent. Additionally, fiber cement boards can easily accommodate insulation materials, enhancing energy efficiency in buildings. This adaptability makes them a favored choice among architects and builders alike, ensuring they meet the diverse needs of modern construction.

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

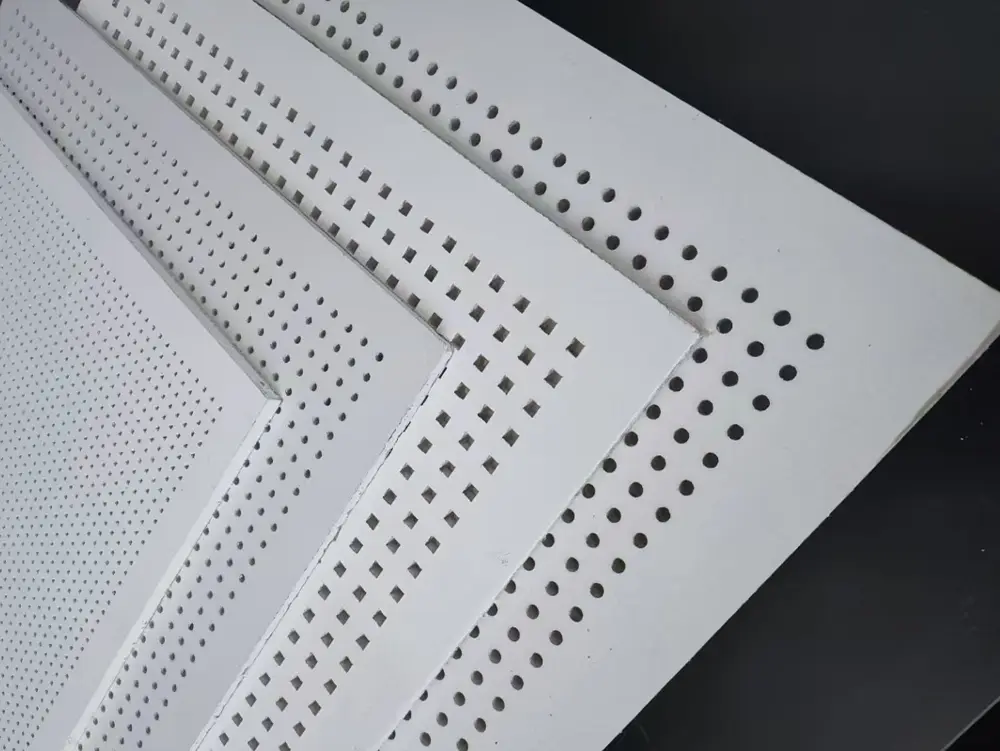

LEAO®Deco Ceiling LEAO® Perforated Ceiling

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel