How to Choose the Right Fiber Cement Floor Underlay for Your Home

Choosing the right Fiber Cement Floor Underlay for your home is a crucial decision that impacts both comfort and durability. According to a report by the Global Cement Market, the fiber cement underlayment segment is projected to see significant growth, with an expected compound annual growth rate (CAGR) of 5.1% from 2021 to 2026. This increase is driven by the rising demand for sustainable and moisture-resistant flooring solutions in residential construction.

Fiber Cement Floor Underlay not only provides superior sound insulation and thermal performance but also enhances the longevity of your flooring system. Therefore, understanding the various types and their specific applications is essential for homeowners looking to make informed decisions that align with their lifestyle needs and environmental considerations.

Understanding the Different Types of Fiber Cement Floor Underlay

When selecting the right fiber cement floor underlay for your home, understanding the different types available is crucial. Fiber cement underlayments are known for their durability and moisture resistance, making them an excellent choice for various flooring types, including vinyl plank flooring. One of the primary advantages of fiber cement underlay is its ability to provide superior sound and thermal insulation, which enhances the overall comfort of your living space.

There are several types of fiber cement floor underlays, each designed to meet specific needs. Some are excellent for moisture-prone areas, like basements and bathrooms, while others offer enhanced resistance to wear and tear. When choosing the right underlay, consider factors such as the level of sound dampening required, moisture levels in your area, and the type of flooring being installed. This understanding will help ensure that you select the most appropriate underlayment to maximize the performance and longevity of your flooring investment.

Evaluating the Key Features to Look for in Fiber Cement Underlay

When selecting the right fiber cement floor underlay for your home, it's essential to evaluate key features that influence performance, durability, and comfort. A recent industry report by the Flooring Manufacturers Association highlights that choosing an underlay with excellent moisture resistance can significantly reduce the risks of mold and mildew, which can threaten both your flooring and health. Additionally, underlays with soundproofing qualities can improve acoustic comfort, especially in multi-story homes, where noise transfer can be an issue.

Tips: Look for fiber cement underlays that include a manufacturer’s warranty, which often indicates a higher quality product and trust in its durability. Furthermore, consider the thickness of the underlay, as a thicker option can provide better insulation and comfort underfoot, leading to an overall enhanced living environment.

The weight of fiber cement products typically ranges from 1.6 to 2.5 pounds per square foot, which can provide stability and support to your flooring system. It’s also crucial to check if the underlay meets local building codes and eco-friendly certifications, ensuring that your choice not only benefits your home but also contributes positively to the environment.

Assessing the Environmental Impact and Sustainability of Your Underlay Choice

When selecting a fiber cement floor underlay for your home, it’s essential to assess the environmental impact and sustainability of your choice. The production process of fiber cement often involves raw materials like cement, cellulose fibers, and silica. Understanding the sourcing of these materials is crucial; opting for products that utilize recycled content or sustainably sourced fibers can significantly reduce your ecological footprint. Additionally, seeking manufacturers who prioritize eco-friendly production methods can further enhance the sustainability of your flooring project.

Another consideration is the longevity and durability of fiber cement underlays. A longer-lasting product typically results in less waste, as it reduces the frequency of replacements. Choosing a high-quality underlay that minimizes wear and tear not only benefits the environment by decreasing waste but also supports energy efficiency within the home. Insulation properties of fiber cement can contribute to better temperature regulation, leading to lower energy consumption. Ultimately, making informed choices regarding the environmental implications of your flooring materials can foster a more sustainable living environment while maintaining aesthetic and functional quality.

Choosing the Right Thickness: How It Affects Soundproofing and Insulation

When selecting the right fiber cement floor underlay for your home, one critical factor to consider is the thickness of the material. The thickness directly impacts both soundproofing and thermal insulation, influencing the overall comfort and ambiance of your living spaces. Thicker underlays can significantly reduce noise transfer between floors, making them an ideal choice for multi-story homes or apartments where sound can easily travel. Additionally, a thicker underlay can provide better insulation, helping to maintain temperature year-round and potentially reducing energy costs.

Tips for Choosing Thickness: Look for underlays that range between 3mm to 5mm thick for optimal balance. A 5mm thickness may be suitable for spaces where noise reduction is essential, while a 3mm option can work well if you're more focused on cost-effectiveness and weight limitations. It’s essential to assess the flooring materials above the underlay as well, as heavier flooring might require a sturdier underlay to provide adequate support and performance.

Moreover, considering the specific use of the space can guide your choice. For instance, underlays in high-traffic areas may benefit from additional thickness to withstand wear and tear. Conversely, in less frequented areas like guest rooms, a standard thickness may suffice while saving on material costs. Always remember that the right thickness leads to enhanced comfort and durability in your home's flooring.

How to Choose the Right Fiber Cement Floor Underlay for Your Home - Choosing the Right Thickness: How It Affects Soundproofing and Insulation

| Thickness (mm) |

Soundproofing Rating (STC) |

Insulation Value (R-Value) |

Ideal Use Case |

| 6 |

30 |

1.1 |

Residential Living Areas |

| 10 |

33 |

1.5 |

Commercial Spaces |

| 12 |

35 |

1.8 |

High Foot Traffic Areas |

| 15 |

38 |

2.0 |

Industrial Settings |

Installation Tips for Achieving the Best Performance from Your Fiber Cement Underlay

When installing fiber cement floor underlay, proper technique is key to ensuring optimal performance. First, it’s essential to prepare the subfloor thoroughly. Ensure it is clean, dry, and level, as any imperfections could affect the underlay’s installation and longevity. If necessary, use a self-leveling compound to fill in any low spots.

Another important tip is to stagger the seams of the underlay. This technique helps distribute stress more evenly across the floor, minimizing potential weak points. Make sure to leave a small gap at the perimeter of the room, allowing for expansion and contraction with temperature changes.

Finally, consider using a vapor barrier if you are installing the underlay in moisture-prone areas, such as basements or bathrooms. This additional layer protects against moisture buildup, which could compromise the integrity of the fiber cement underlay and ultimately the flooring above. By following these tips, you can achieve a durable and resilient floor that will perform well for years to come.

Fiber Cement Floor Underlay Performance Ratings

This bar chart illustrates the performance ratings of various features of fiber cement floor underlay. Each feature is rated on a scale from 1 to 10, with higher numbers indicating better performance. The chart highlights important characteristics such as water resistance, sound insulation, thermal insulation, durability, and cost-effectiveness.

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

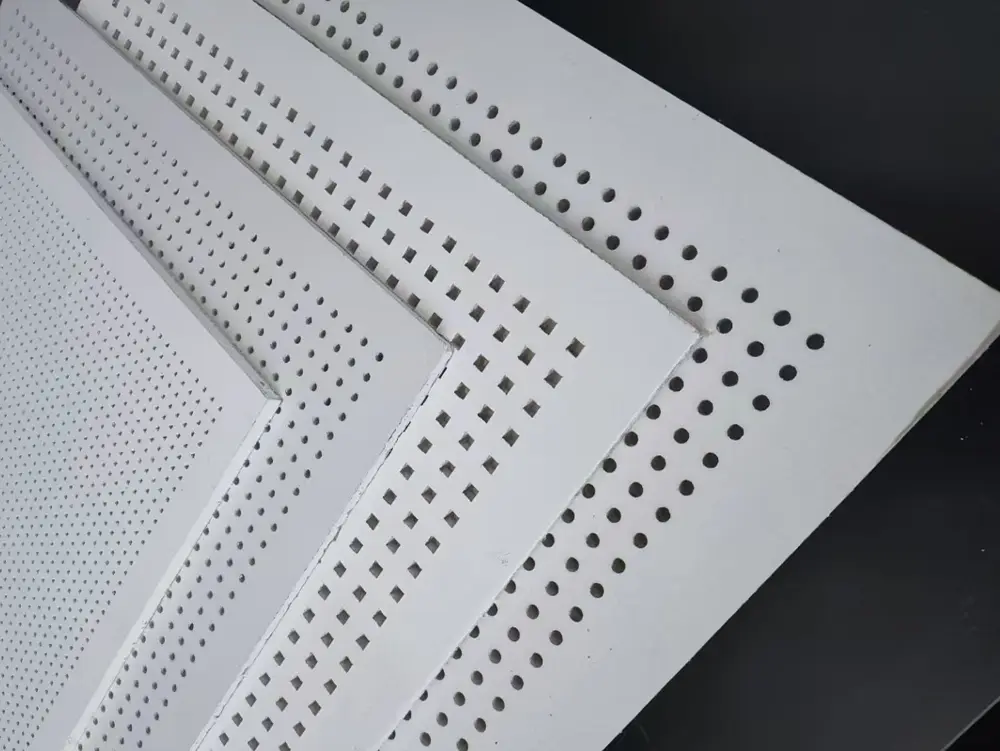

LEAO®Deco Ceiling LEAO® Perforated Ceiling

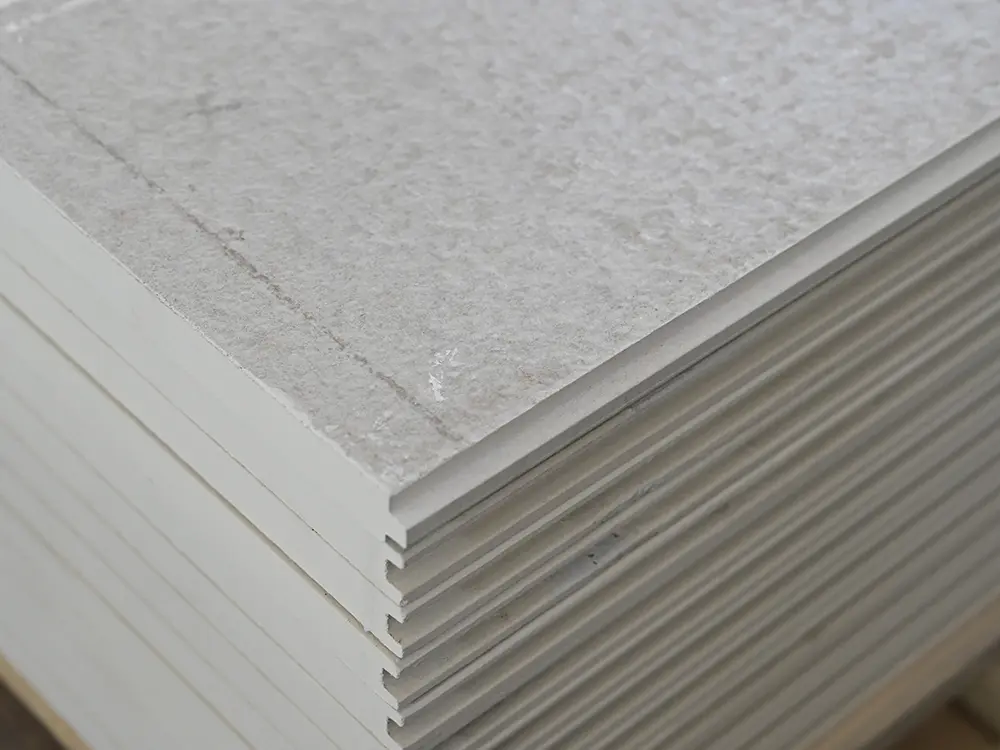

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel