How to Choose the Best Fiber Cement Formwork Board for Your Project

When selecting the optimal Fiber Cement Formwork Board for your construction project, it is crucial to consider various practical factors that can significantly impact both the quality of the build and cost-effectiveness. According to Dr. Emily Johnson, a leading expert in construction materials, “The right Fiber Cement Formwork Board can make a substantial difference in the long-term durability and efficiency of your project.” This statement underscores the importance of understanding the unique advantages offered by fiber cement as a material, particularly in formwork applications.

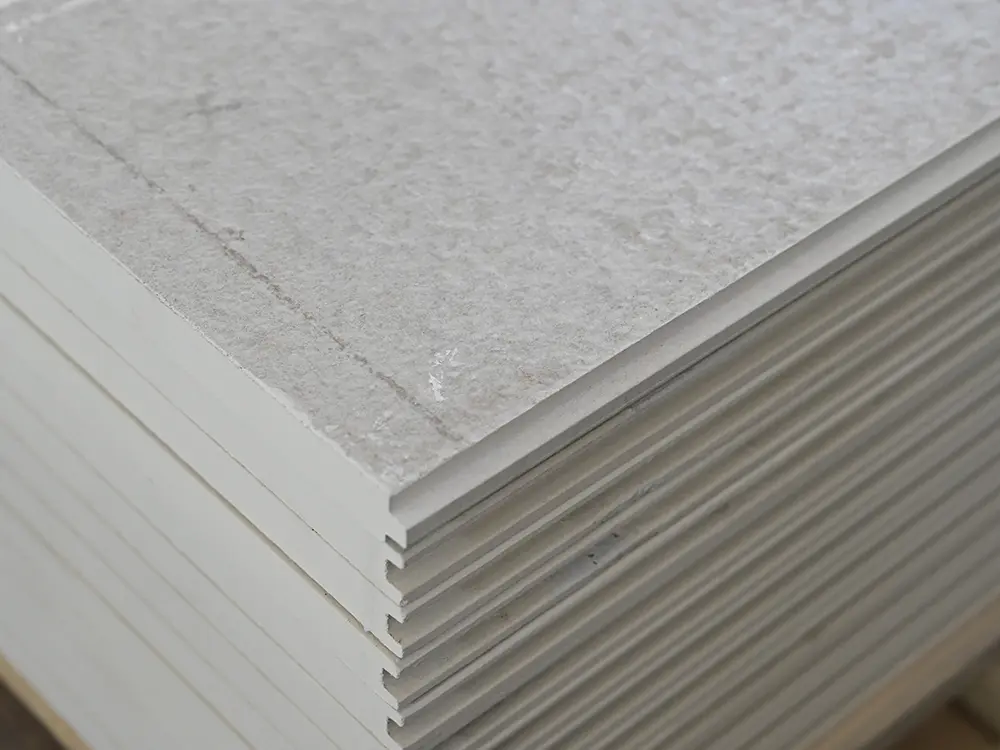

Fiber Cement Formwork Boards are renowned for their resilience, moisture resistance, and ability to provide a smooth finish. However, not all boards are created equal. Project managers and builders must assess key specifications such as thickness, weight, and fire resistance to determine which product aligns best with their specific project needs. By doing so, they can ensure optimal performance and longevity, ultimately leading to enhanced safety and reduced maintenance costs throughout the lifecycle of the structure.

Understanding Fiber Cement Formwork Boards and Their Benefits

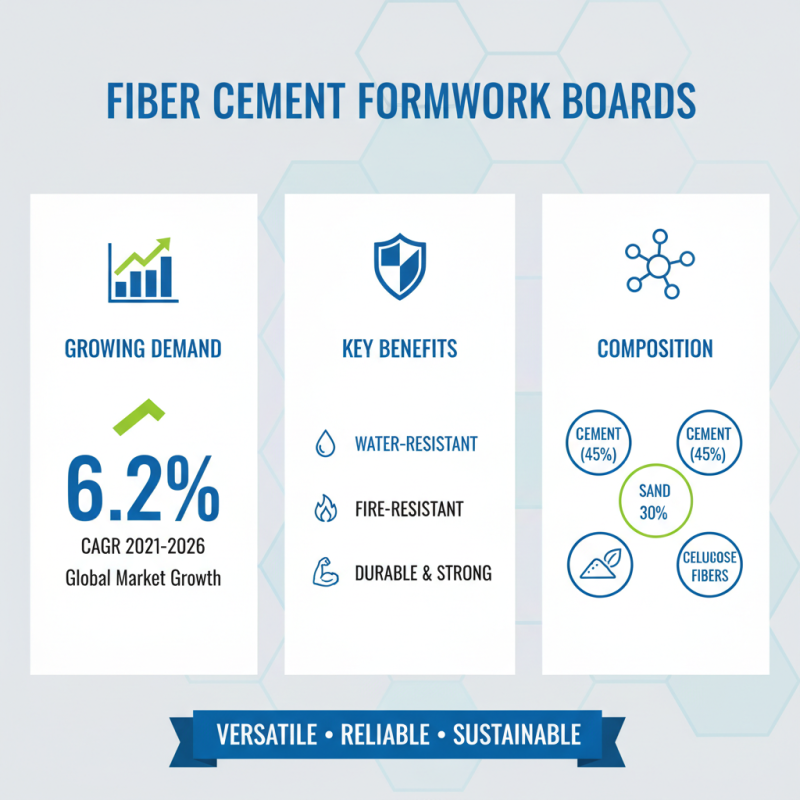

Fiber cement formwork boards have gained popularity in the construction industry due to their outstanding durability and versatility. These boards are primarily composed of cement, sand, and cellulose fibers, which contribute to their strength and resistance to water and fire. According to a report by the Global Construction Materials Market, the demand for fiber cement boards is projected to grow at a compound annual growth rate (CAGR) of 6.2% between 2021 and 2026, which highlights their escalating acceptance in various construction projects.

One of the primary benefits of fiber cement formwork boards is their environmental sustainability. These boards are often made from eco-friendly materials and contribute to reducing the carbon footprint of construction projects. A study by the Environmental Protection Agency indicates that using sustainable materials in construction can lead to a reduction of greenhouse gas emissions by up to 30%. Additionally, fiber cement boards are resistant to termites and other pests, making them a reliable choice for long-term structural applications. Their longevity and low maintenance requirements further enhance their appeal, as projects can benefit from reduced lifecycle costs and greater return on investment.

By understanding the advantages of fiber cement formwork boards, project managers and builders can make informed decisions that not only meet structural needs but also align with sustainability goals. With increasing industry focus on green building practices, choosing the right formwork board becomes essential for achieving both functionality and environmental efficiency in modern construction.

Key Factors to Consider When Choosing Fiber Cement Formwork Boards

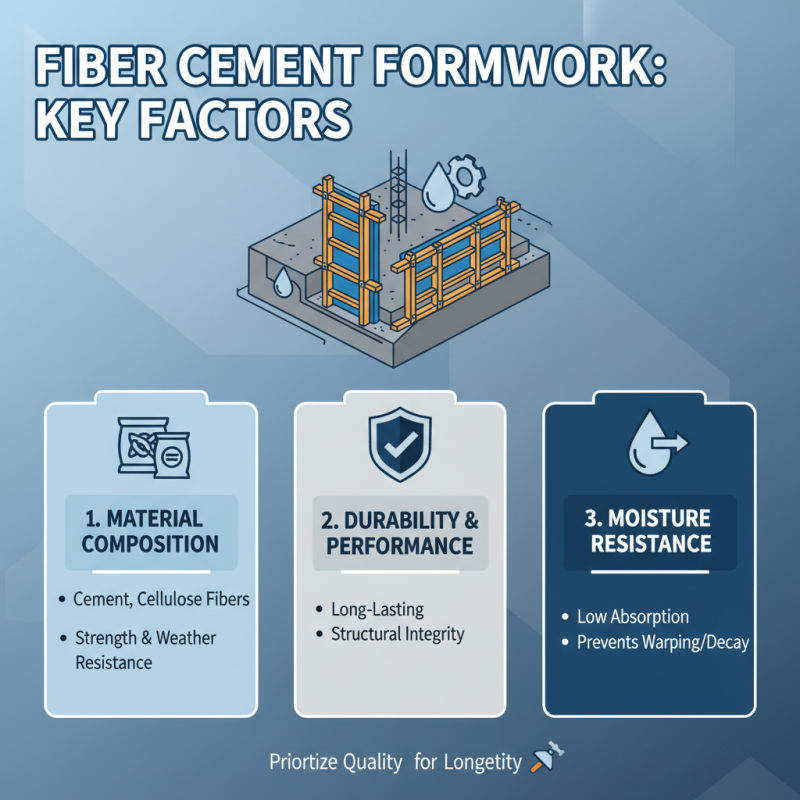

When selecting the best fiber cement formwork board for your project, several key factors must be considered to ensure optimal performance and durability. One crucial aspect is the thickness of the boards, which can significantly impact their strength and insulation properties. Studies show that thicker boards, typically ranging from 12mm to 18mm, offer enhanced structural support and reduce the risk of warping or cracking under extreme conditions. This is particularly important in large-scale construction projects where stability and reliability are paramount.

Another vital consideration is the moisture resistance of the fiber cement boards. According to industry reports, moisture can lead to degradation and reduced longevity of the formwork. High-quality fiber cement boards exhibit low water absorption rates, often less than 15%, which is essential for maintaining their integrity over time. Furthermore, assessing the board's compatibility with various building materials can influence your choice, as some boards are specifically designed to work seamlessly with different concrete mixes and curing processes, thereby improving the overall efficiency of the construction project.

Comparing Different Types of Fiber Cement Formwork Boards

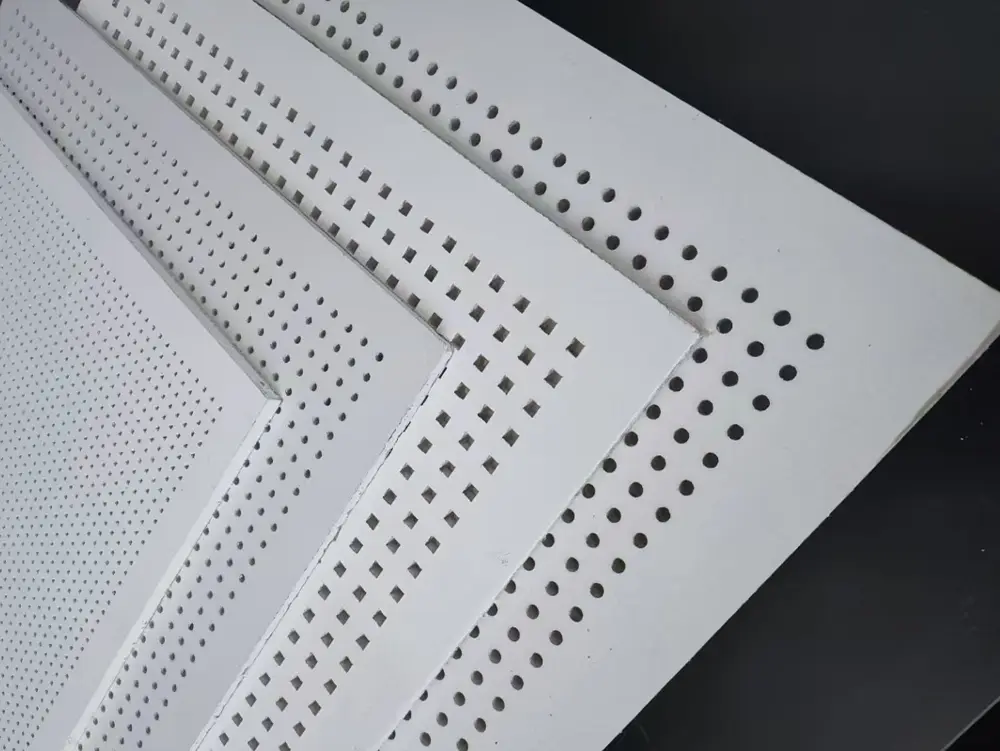

When selecting the best fiber cement formwork board for your project, it's essential to compare the various types available in the market. Fiber cement boards are primarily categorized into two types: standard and high-density boards.

Standard boards offer good durability and are commonly used for lightweight constructions. They are easy to handle and install but may not withstand heavy loads or harsh environmental conditions as effectively as their high-density counterparts.

On the other hand, high-density fiber cement boards are designed for more demanding applications. These boards provide superior strength and moisture resistance, making them suitable for projects that require enhanced durability, such as in commercial or industrial settings.

Additionally, some boards come with a textured surface, which can improve adhesion for subsequent layers of material, like plaster or paint. When making a decision, consider factors like the load requirements, exposure to elements, and installation ease, as these will significantly impact the performance and longevity of the formwork used in your construction project.

Tips for Evaluating the Durability and Performance of Formwork Boards

When selecting a fiber cement formwork board for your project, it is essential to prioritize durability and performance. Start by assessing the material composition of the boards. High-quality fiber cement boards typically contain a mix of cement, cellulose fibers, and other additives that enhance strength and weather resistance. Look for specifications related to moisture absorption, which can affect the longevity and structural integrity of the boards when exposed to wet conditions.

Next, consider the board's thickness and weight. Thicker boards tend to offer better resistance to warping and cracking, especially in fluctuating weather conditions. Evaluate the performance ratings provided by manufacturers, focusing on parameters such as compressive strength and flexural strength. These ratings can serve as an indicator of how well the boards can handle the stresses encountered during construction. Additionally, check for any certifications or testing standards that prove the boards meet industry requirements, ensuring that they will perform reliably throughout the duration of your project.

Financing and Budgeting for Fiber Cement Formwork Board Projects

When planning a project involving fiber cement formwork boards, budgeting and financing play crucial roles in ensuring success. According to the Fiber Cement Product Industry Report 2022, the average cost for fiber cement formwork boards ranges from $2.50 to $5.00 per square foot, depending on thickness and finish. This price point necessitates careful financial planning, especially for large-scale constructions. Project managers should allocate a significant portion of their budgets not only for the material itself but also for associated costs like transportation, labor, and installation.

Tips: Consider obtaining multiple quotes from suppliers to compare prices and explore bulk buying options. Many manufacturers offer discounts for larger orders, which can lead to considerable savings.

In addition, financing options such as construction loans or business lines of credit may be available to streamline project costs, especially in tight budget scenarios. It's essential to account for potential fluctuations in material costs that might arise from supply chain disruptions. The 2023 Construction Cost Trends report highlights that construction material prices can increase by 3% to 7% annually. To mitigate the risks associated with these changes, securing financial resources in advance can provide a buffer against unexpected expenses during project execution.

Tips: Always maintain an emergency fund of at least 10% of your total budget to accommodate unforeseen developments, ensuring that your project remains on track without compromising quality.

How to Choose the Best Fiber Cement Formwork Board for Your Project - Financing and Budgeting for Fiber Cement Formwork Board Projects

| Project Type |

Estimated Quantity (sq ft) |

Cost per Unit ($) |

Total Cost ($) |

Budget Category |

| Residential Building |

1500 |

1.50 |

2250 |

Construction |

| Commercial Building |

3000 |

2.00 |

6000 |

Construction |

| Industrial Application |

2000 |

1.75 |

3500 |

Commercial |

| Institutional Project |

4000 |

2.50 |

10000 |

Government |

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

LEAO®Deco Ceiling LEAO® Perforated Ceiling

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel