Why Digital Print Boards Are Revolutionizing Custom Printing Solutions

In the ever-evolving landscape of custom printing solutions, Digital Print Boards are emerging as a transformative force. These innovative platforms not only streamline the printing process but also expand the creative possibilities for designers and businesses alike. By combining advanced digital technology with versatile material options, Digital Print Boards are redefining how custom prints are produced, offering unprecedented accuracy and efficiency.

As businesses strive to differentiate themselves in a competitive market, the ability to create high-quality, bespoke products quickly and cost-effectively has become essential. Digital Print Boards meet this demand by allowing for rapid prototyping and flexible design alterations, accommodating the unique needs of clients without sacrificing quality. This article will explore the various benefits and applications of Digital Print Boards, demonstrating how they are revolutionizing the custom printing landscape and empowering creators to push the boundaries of what is achievable in print design.

The Evolution of Digital Print Boards in Custom Printing Technology

The rise of digital print boards has fundamentally transformed the landscape of custom printing technology. Over the years, these boards have evolved from simple designs to sophisticated systems capable of producing intricate patterns and high-quality images with unparalleled precision. This transformation has allowed businesses to meet the demanding needs of their clients, offering a level of customization that was previously unattainable.

Tips: When considering a digital print board for your project, focus on the board’s resolution and color accuracy. High-resolution boards will produce sharper images, while boards with a wider color gamut can capture more vibrant colors, enhancing the overall visual appeal. Additionally, explore options that support various substrates to expand your printing capabilities.

Furthermore, the integration of advanced software has streamlined the printing process, enabling designers to create and modify designs with ease. As technology continues to advance, the use of artificial intelligence in digital print boards could enhance workflow efficiency and result in even more creative possibilities. Investing in the latest digital print technology can significantly boost your printing business’s competitive edge.

Key Advantages of Digital Print Boards Over Traditional Printing Methods

Digital print boards are transforming the landscape of custom printing solutions, primarily due to their numerous advantages over traditional printing methods. One of the key benefits is the ability to produce high-quality prints with exceptional detail and vibrant colors. Unlike traditional methods that often require extensive setup and preparation, digital print boards enable quick adjustments and modifications, which is particularly beneficial for short runs and custom projects. This flexibility allows businesses to cater to different customer needs without incurring significant overhead costs.

Additionally, digital print boards offer environmentally friendly options that appeal to eco-conscious consumers. With reduced waste generated during the printing process and the ability to use sustainable materials, companies can align their practices with green initiatives. Furthermore, the speed of digital printing means faster turnaround times, enabling businesses to fulfill orders more efficiently. Overall, these advantages position digital print boards as a game-changer in the custom printing industry, providing quality, flexibility, and sustainability that traditional methods struggle to match.

Exploring Applications: Where Digital Print Boards Shine in Custom Solutions

Digital print boards are transforming the landscape of custom printing solutions across various industries. Applications in advertising, packaging, and art reproduction showcase how these innovative boards are being utilized effectively. For instance, a report by Smithers Pira indicates that the global digital printing market is expected to reach $23 billion by 2024, driven primarily by demand for personalized and short-run print jobs. Digital print boards facilitate this shift by enabling faster turnaround times and enhanced customization options, empowering businesses to engage their customers effectively.

Moreover, the versatility of digital print boards allows for a broad range of substrates, expanding their utility in sectors such as interior design and event branding. According to a survey from NPD Group, 60% of consumers prefer personalized products, reflecting a significant market trend towards customization. With digital print boards, companies can create tailor-made solutions that cater to unique consumer preferences, whether through vivid graphics on signage or bespoke packaging options. This capability not only meets evolving consumer expectations but also enhances brand loyalty, making digital print boards a crucial element in the future of custom printing solutions.

Why Digital Print Boards Are Revolutionizing Custom Printing Solutions - Exploring Applications: Where Digital Print Boards Shine in Custom Solutions

| Application Area |

Benefits |

Materials Used |

Typical Print Size |

Print Resolution |

| Signage |

High visibility, weather-resistant |

Vinyl, acrylic |

Up to 10 ft |

300 DPI |

| Promotional Materials |

Customizable, cost-effective |

Paper, cardstock |

Varies |

600 DPI |

| Packaging |

Eye-catching designs, minimal setup |

Cardboard, plastic |

Standard sizes available |

300-1200 DPI |

| Apparel |

Full-color designs, no minimums |

Cotton, polyester |

Varies by garment |

1200 DPI |

| Interior Decor |

Unique designs, custom sizes |

Canvas, wallpaper |

Up to 10 ft |

300 DPI |

Future Trends: What to Expect from Digital Print Boards by 2025

The landscape of custom printing solutions is rapidly evolving, particularly with the advent of digital print boards. By 2025, we can expect several key trends to emerge, shaping the future of this technology. As digital print boards become increasingly sophisticated, they will likely offer unparalleled versatility, enabling businesses to produce highly personalized products on demand. This capability will cater not only to consumer demands but also to niche markets requiring unique, tailor-made solutions.

Additionally, sustainability will take center stage in the development of digital print boards. Innovations in eco-friendly inks and substrates will revolutionize the production process, reducing waste and minimizing environmental impact. The integration of advanced automation and artificial intelligence will also enhance efficiency, allowing companies to streamline operations while maintaining high-quality outputs. As these trends converge, businesses will find themselves better equipped to meet the diverse needs of their clientele, setting the stage for unprecedented growth in the custom printing sector.

Enhancing Sustainability: The Role of Digital Print Boards in Eco-Friendly Printing Practices

Digital print boards are emerging as a pivotal solution in the realm of eco-friendly printing practices. Unlike traditional printing methods, which often rely on extensive chemical processes and create significant waste, digital printing minimizes resource usage and environmental impact.

The shift towards digital print boards allows businesses to optimize their production processes by using only what is necessary, significantly reducing material waste. This technology utilizes high-efficiency inks and substrates that are more sustainable, aligning with the global movement towards greener manufacturing.

Moreover, the flexibility offered by digital print boards encourages companies to implement just-in-time printing, effectively eliminating surplus inventory. By producing only what is needed, brands can lessen their footprint on the environment and contribute to the reduction of excess stock that often ends up in landfills.

Additionally, advancements in recyclable and biodegradable materials used in digital print boards exemplify the commitment to sustainability, ensuring that even the end products support eco-friendly practices. Through these innovative methods, digital print boards not only enhance customization but also play a crucial role in fostering a more sustainable future for the printing industry.

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

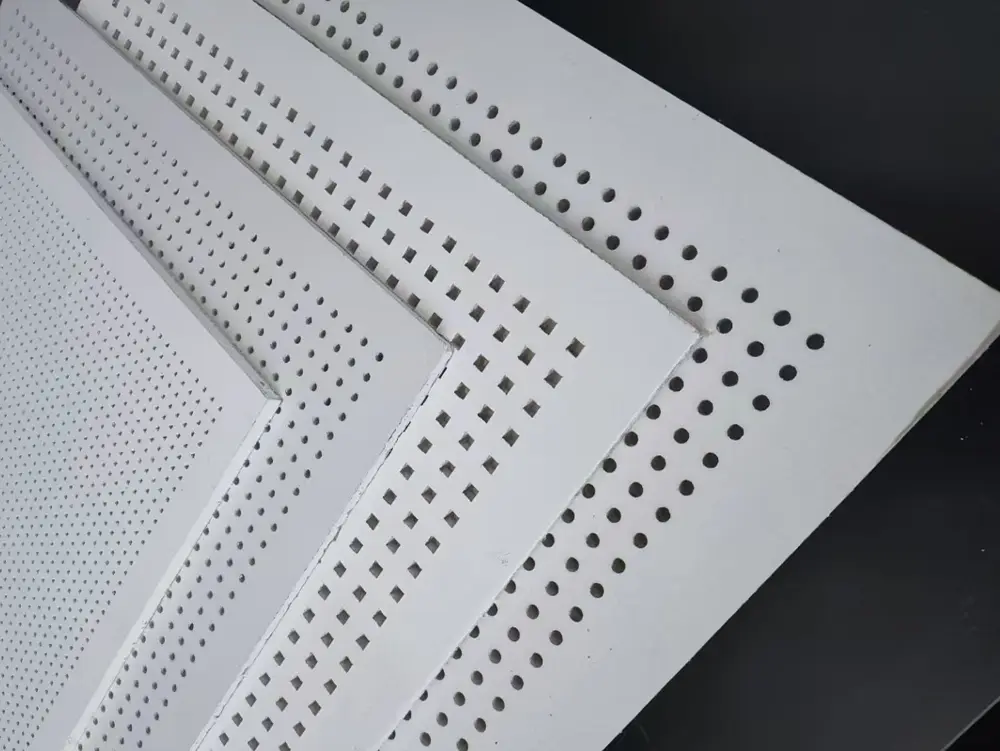

LEAO®Deco Ceiling LEAO® Perforated Ceiling

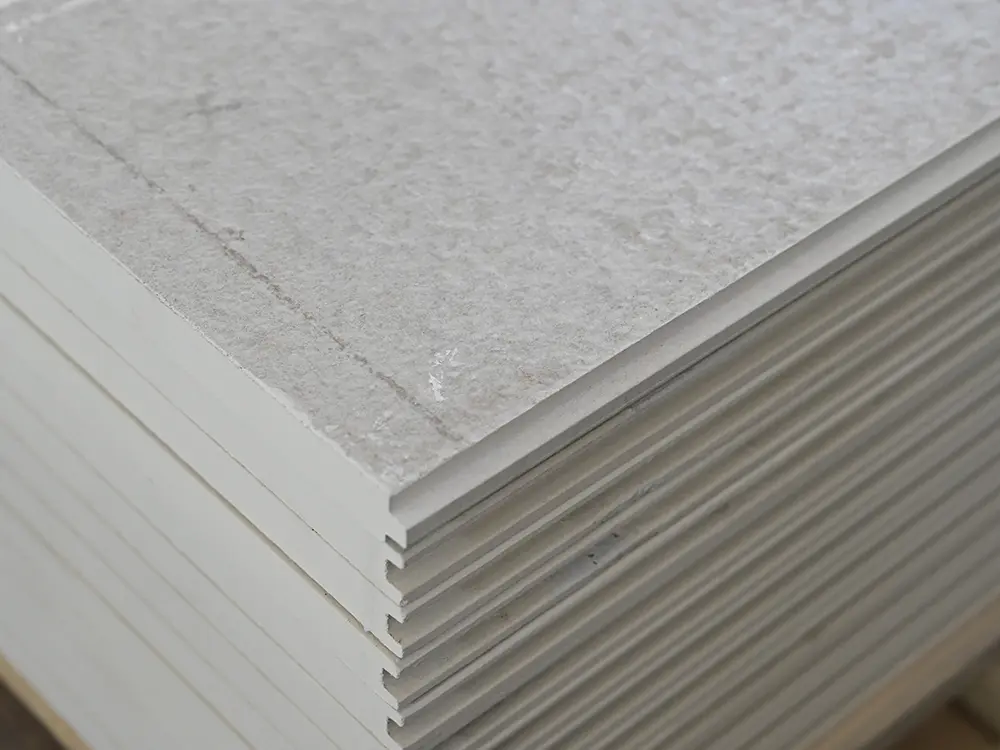

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel