Finding Reliable Suppliers for Premium Best Fiber Cement Woodgrain Boards

In recent years, the demand for durable and aesthetically pleasing building materials has led to a surge in popularity for Fiber Cement Woodgrain Boards.

These innovative products combine the natural beauty of wood with the strength and resilience of fiber cement, making them an ideal choice for both residential and commercial applications.

As we look ahead to the technological advancements expected in 2025, it's essential for businesses to understand how to find reliable suppliers that align with these new trends.

This blog will explore the evolving landscape of fiber cement products, highlight the key factors to consider when selecting suppliers, and provide practical tips on leveraging advancements in technology to ensure procurement of top-quality Fiber Cement Woodgrain Boards.

Join us as we navigate through the best practices for sourcing these premium materials in a competitive market.

Understanding Fiber Cement Woodgrain Boards: Features and Benefits

Fiber cement woodgrain boards are an innovative building material that beautifully combines the aesthetic appeal of wood with the durability of cement. These boards mimic the warmth and texture of traditional wood while being resistant to moisture, pests, and fire. Thanks to their composite nature, they require less maintenance than natural wood, making them a popular choice for both residential and commercial applications. Given their longevity and versatility, understanding their features and benefits is essential when considering options for construction or renovation projects.

When searching for reliable suppliers of fiber cement woodgrain boards, it's advisable to explore the product specifications thoroughly. Look for boards that offer a high density and UV resistance, ensuring they maintain their appearance over time. Additionally, check for certifications that validate the product's quality and sustainability.

Tip: Always request samples before making a bulk order to assess the board's look and feel firsthand. Another key tip is to read customer reviews and testimonials to gauge the supplier's reliability and customer service history. This due diligence can help ensure that you invest in high-quality materials that will enhance your project’s aesthetic and longevity.

Types of Fiber Cement Woodgrain Boards and Their Applications

Fiber cement woodgrain boards are increasingly popular in modern construction due to their durability and aesthetic appeal. These boards come in various types, each with specific applications that make them suitable for different projects. Traditional woodgrain boards provide the classic look of natural wood while ensuring resistance to moisture, pests, and fire. This makes them ideal for exterior cladding in regions with harsh weather conditions.

Another type is the textured fiber cement board, which mimics the appearance of wood while offering enhanced durability. These boards are commonly used in residential settings for siding or decorative features, blending seamlessly into the overall design. Additionally, fiber cement boards come in pre-finished options, reducing installation time and maintenance concerns. Whether for commercial or residential use, selecting the right type of fiber cement woodgrain board can significantly impact the project’s longevity and visual appeal.

How to Evaluate the Quality of Fiber Cement Boards

When it comes to sourcing premium fiber cement woodgrain boards, evaluating quality is paramount. The first aspect to consider is the manufacturing process. High-quality fiber cement boards should be produced using advanced technology that ensures a consistent and durable product. Look for suppliers who adhere to industry standards and certifications, as these often indicate a commitment to superior quality. Additionally, inspect the board's texture and finish; true woodgrain patterns should be visually appealing and feel authentic to the touch.

Another important factor is the material composition. Premium fiber cement boards typically contain higher cement content and natural fibers, which enhance their resilience and longevity. Check for any additives that might compromise the integrity of the boards, such as fillers that could weaken the material. Lastly, review customer feedback and case studies to gauge the performance of the boards in real-world applications. Reliable suppliers will often provide references or testimonials that highlight their products' durability and aesthetic appeal, giving you a better understanding of what to expect from your investment.

Finding Reliable Suppliers for Premium Best Fiber Cement Woodgrain Boards - How to Evaluate the Quality of Fiber Cement Boards

| Supplier Location |

Board Thickness (mm) |

Surface Finish |

Warranty Duration |

Fire Resistance Rating |

Water Absorption (%) |

| USA |

12 |

Textured |

10 years |

A2 |

7 |

| Canada |

10 |

Smooth |

15 years |

B1 |

5 |

| Australia |

15 |

Woodgrain |

20 years |

A1 |

4 |

| Germany |

18 |

Natural |

25 years |

B2 |

6 |

| Taiwan |

11 |

Polished |

12 years |

A2 |

8 |

Key Factors in Selecting Reliable Suppliers for Fiber Cement Products

When it comes to sourcing premium fiber cement woodgrain boards, finding reliable suppliers is crucial for maintaining quality and ensuring sustainable production. Key factors in selecting these suppliers include their experience in the industry, production capabilities, and adherence to quality standards. Recent reports indicate that the fiber cement board market is expected to witness a significant growth rate, driven by increasing demand in construction and renovation projects. This is indicative of the rising importance of choosing the right supplier, as the quality of materials can directly impact project outcomes.

Tip: Always request samples from potential suppliers to assess the quality and performance of their fiber cement products before making bulk purchases.

Additionally, evaluating a supplier's commitment to sustainability and environmental practices can provide insights into their long-term viability and ethical considerations. The global nanocellulose market, for instance, is projected to grow remarkably, suggesting a shift towards more eco-friendly materials in construction. Understanding these trends can help businesses identify forward-thinking suppliers who align with industry developments.

Tip: Research supplier reviews and case studies to gather insights into their reliability and performance track record in meeting project needs.

Sustainability and Durability: Why Fiber Cement Boards Stand Out

Fiber cement boards are redefining the construction and design landscape with their unparalleled sustainability and durability. According to a recent industry report, the global fiber cement board market is expected to reach USD 22.9 billion by 2026, growing at a CAGR of 5.7%. This surge can be attributed to the material's resistance to extreme weather, fire, and pests, making it an ideal choice for both residential and commercial applications. Additionally, fiber cement boards are made from sustainable materials such as cellulose fibers, sand, and cement, significantly reducing the environmental footprint compared to traditional wood products.

When selecting fiber cement woodgrain boards, consider the following tips to ensure quality and longevity. First, look for suppliers who prioritize eco-friendly manufacturing practices and offer certifications such as LEED or Green Seal. Second, opt for products that undergo rigorous testing for durability and resistance. This not only guarantees longevity but also confirms the manufacturer's commitment to sustainability. Finally, engage with suppliers who provide comprehensive warranties, as this can be an indicator of their confidence in the product’s lifespan.

Incorporating fiber cement boards into your projects not only enhances aesthetic appeal but also aligns with sustainable building practices. With their low maintenance requirements and high durability, these boards represent a smart investment for the future of construction.

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

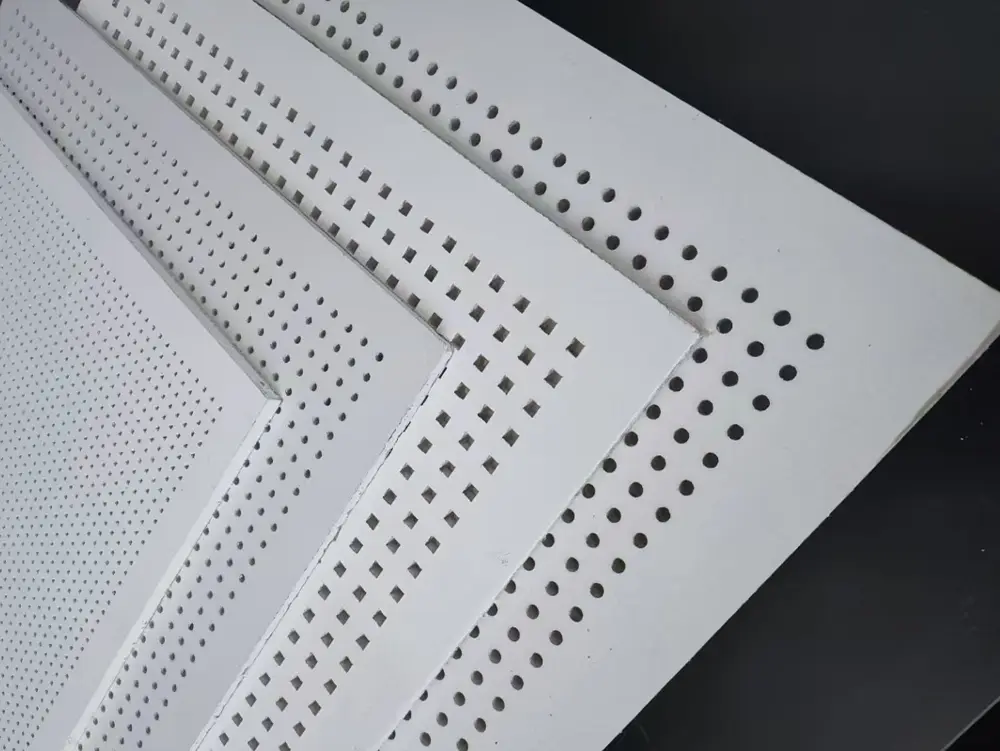

LEAO®Deco Ceiling LEAO® Perforated Ceiling

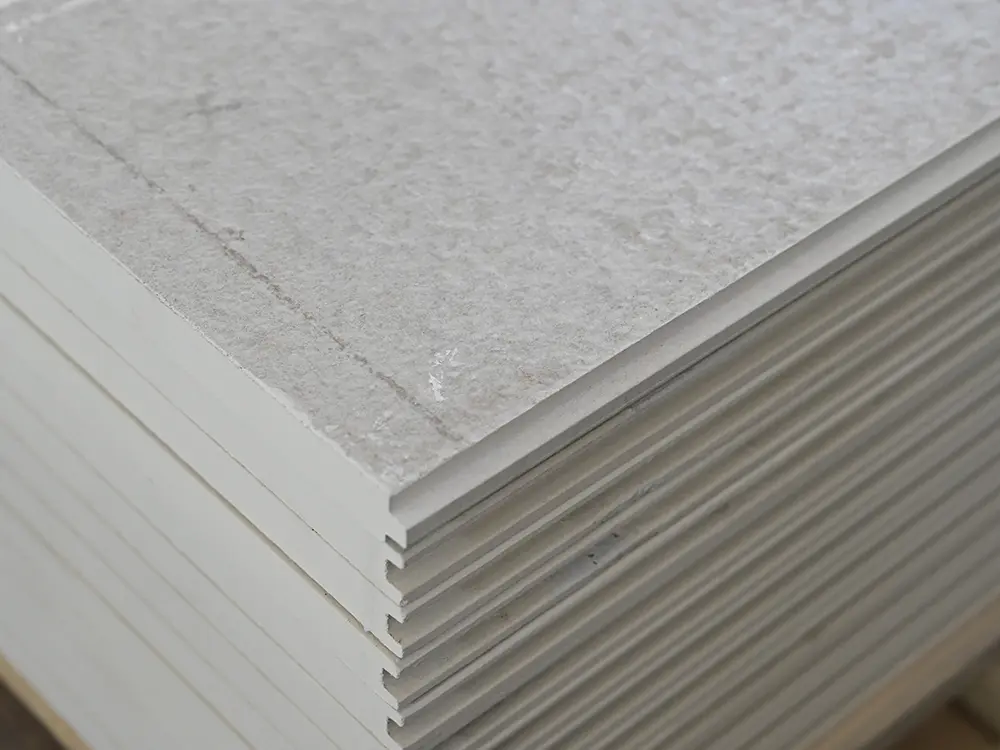

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel