How to Identify Top Suppliers for Best Fiber Cement Partition Boards

In the ever-evolving construction industry, the demand for durable, cost-effective, and versatile materials continues to rise, with the Fiber Cement Partition Board taking center stage. According to a recent report by Research and Markets, the global fiber cement market is expected to reach USD 22.5 billion by 2025, growing at a CAGR of 5.1% during the forecast period. This substantial growth highlights the increasing preference for fiber cement products due to their exceptional performance attributes such as resistance to fire, water, and pests. Identifying top suppliers of Fiber Cement Partition Boards is crucial for builders and contractors aiming to ensure quality and sustainability in their projects. As the sector becomes more competitive, understanding the best suppliers will not only enhance project efficiency but also contribute to long-term cost savings and structural integrity.

Understanding the Fiber Cement Partition Board Market Landscape by 2025

The fiber cement partition board market is poised for significant growth, with projections indicating a market size of approximately USD 15 billion by 2025, driven by increased demand for lightweight and durable building materials. According to a recent report from Grand View Research, the global fiber cement board market is expected to expand at a CAGR of 5.5% over the next few years. This growth can be attributed to the rising trends in sustainable construction practices, which prioritize materials that offer both environmental benefits and long-lasting performance.

In addition, the expanding construction industry in emerging economies is further propelling the market. A report by ResearchAndMarkets highlights that Asia-Pacific is expected to dominate the fiber cement partition board sector, accounting for over 40% of the market share by 2025, owing to rapid urbanization and infrastructural development. As the market landscape evolves, identifying top suppliers who can meet quality, price, and reliability standards will be essential for stakeholders aiming to capitalize on this upward trend in fiber cement products.

Market Share of Fiber Cement Partition Board Suppliers by 2025

Key Factors to Consider When Evaluating Top Suppliers

When evaluating top suppliers for fiber cement partition boards, several key factors can greatly influence your decision-making process. First, assess the supplier's experience and expertise in the industry. A well-established supplier is likely to have a proven track record of delivering quality products and can provide valuable insights into the specific needs of your projects. Consider how long they have been in the business and what their reputation is among other contractors and customers.

Another crucial aspect is the quality of the products offered. Look for suppliers who provide detailed information about their manufacturing processes and the materials used in their fiber cement boards. Certifications and compliance with industry standards can also serve as indicators of quality.

Additionally, it’s important to evaluate their customer service and support. A responsive supplier who offers assistance throughout the ordering and delivery process can significantly enhance the overall experience and help you address any challenges that arise. By focusing on these factors, you can ensure that you select a top-notch supplier that meets your project requirements effectively.

Emerging Trends in Fiber Cement Products for Future Growth

The fiber cement industry is undergoing significant transformations, driven by

innovative manufacturing techniques and evolving consumer preferences. One of the most notable emerging trends is the

increasing demand for sustainable and eco-friendly materials.

Suppliers are now prioritizing the use of recycled content and reducing carbon footprints in their products. This shift not only aligns with global sustainability goals but also resonates with environmentally conscious consumers and businesses.

The fiber cement industry is undergoing significant transformations, driven by

innovative manufacturing techniques and evolving consumer preferences. One of the most notable emerging trends is the

increasing demand for sustainable and eco-friendly materials.

Suppliers are now prioritizing the use of recycled content and reducing carbon footprints in their products. This shift not only aligns with global sustainability goals but also resonates with environmentally conscious consumers and businesses.

Additionally, advancements in technology are paving the way for enhanced

performance and

versatility of fiber cement partition boards. Manufacturers are experimenting with various textures, colors, and finishes, allowing for greater customization that meets the aesthetic needs of modern architecture. Innovations such as

moisture resistance,

fire safety features, and improved durability are becoming standard offerings, setting a higher bar for quality and performance in the market. These trends not only open up new avenues for design but also ensure that fiber cement products can compete effectively with traditional materials in both residential and commercial applications.

Sustainable Practices in Fiber Cement Manufacturing

Sustainable practices in fiber cement manufacturing are becoming increasingly crucial as both consumers and manufacturers prioritize environmental responsibility. The production of fiber cement partition boards involves the use of natural materials, which can be sourced sustainably. By focusing on eco-friendly sourcing and the reduction of waste during the manufacturing process, suppliers can significantly minimize their carbon footprint while producing high-quality products.

Tips for selecting suppliers who prioritize sustainability include evaluating their sourcing methods. Ensure that the raw materials used, such as fibers and cement, are obtained through responsible practices. This might involve choosing suppliers who have certifications for sustainable logging or ISO standards that endorse environmental management. Additionally, assess the supplier’s energy consumption during production; those utilizing renewable energy sources are often more committed to sustainable practices.

Another important aspect is to inquire about the lifecycle considerations of their products. Good suppliers will provide information on the durability and recyclability of their boards, which not only contributes to sustainability but also offers long-term value to projects. Engaging with suppliers who prioritize these practices can ensure that your choice not only meets structural needs but also aligns with a commitment to environmental stewardship.

How to Identify Top Suppliers for Best Fiber Cement Partition Boards - Sustainable Practices in Fiber Cement Manufacturing

| Supplier Type |

Sustainability Practices |

Product Certification |

Production Capacity (units/year) |

Delivery Time (weeks) |

| Local Manufacturer |

Recycled Materials Use |

ISO 14001 |

50,000 |

4 |

| International Supplier |

Water Conservation Techniques |

FSC Certified |

200,000 |

8 |

| Regionally Sourced Supplier |

Energy-Efficient Processes |

LEED Compliant |

100,000 |

6 |

| Small-scale Artisan Producer |

Low Carbon Footprint |

EcoLabel Certified |

10,000 |

3 |

| Composite Manufacturer |

Closed-Loop Production System |

Green Guard Certified |

150,000 |

5 |

Evaluating Supplier Reliability: Quality, Pricing, and Service

Evaluating supplier reliability is crucial for businesses looking to source top-quality fiber cement partition boards. The process involves thorough assessment of key factors such as quality, pricing, and service offerings to ensure that suppliers meet the rigorous standards required. It is essential to align this evaluation with frameworks like the Foreign, Commonwealth and Development Office (FCDO) evaluation policy, which emphasizes a common understanding of evaluation principles and minimum standards. This policy helps organizations to streamline their supplier selection processes by establishing clear expectations regarding reliability and performance.

Evaluating supplier reliability is crucial for businesses looking to source top-quality fiber cement partition boards. The process involves thorough assessment of key factors such as quality, pricing, and service offerings to ensure that suppliers meet the rigorous standards required. It is essential to align this evaluation with frameworks like the Foreign, Commonwealth and Development Office (FCDO) evaluation policy, which emphasizes a common understanding of evaluation principles and minimum standards. This policy helps organizations to streamline their supplier selection processes by establishing clear expectations regarding reliability and performance.

Moreover, utilizing advanced methodologies such as the Analytical Hierarchy Process (AHP) can enhance decision-making regarding supplier quality. AHP allows managers to weigh different criteria based on their perceptions and priorities, leading to more informed choices. Incorporating data analytics, including deep learning and machine learning, can further refine the supplier evaluation process by predicting performance outcomes and improving supply chain management efficiency. By combining these strategies, businesses can identify suppliers who not only offer competitive pricing but also provide exceptional service and product reliability, ultimately contributing to operational success.

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

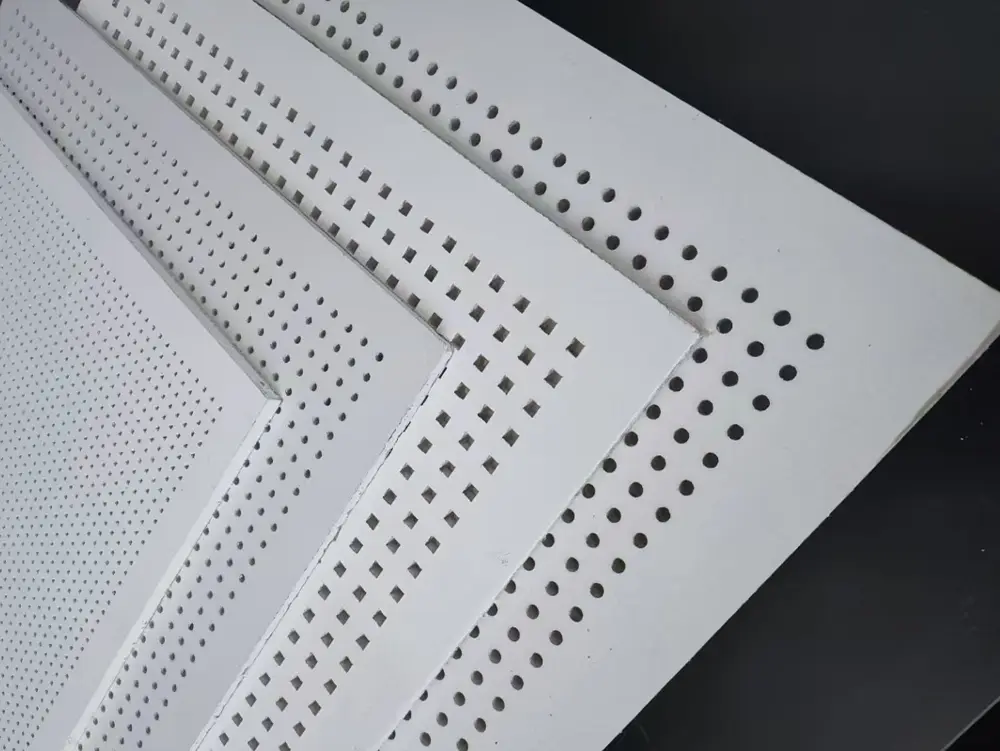

LEAO®Deco Ceiling LEAO® Perforated Ceiling

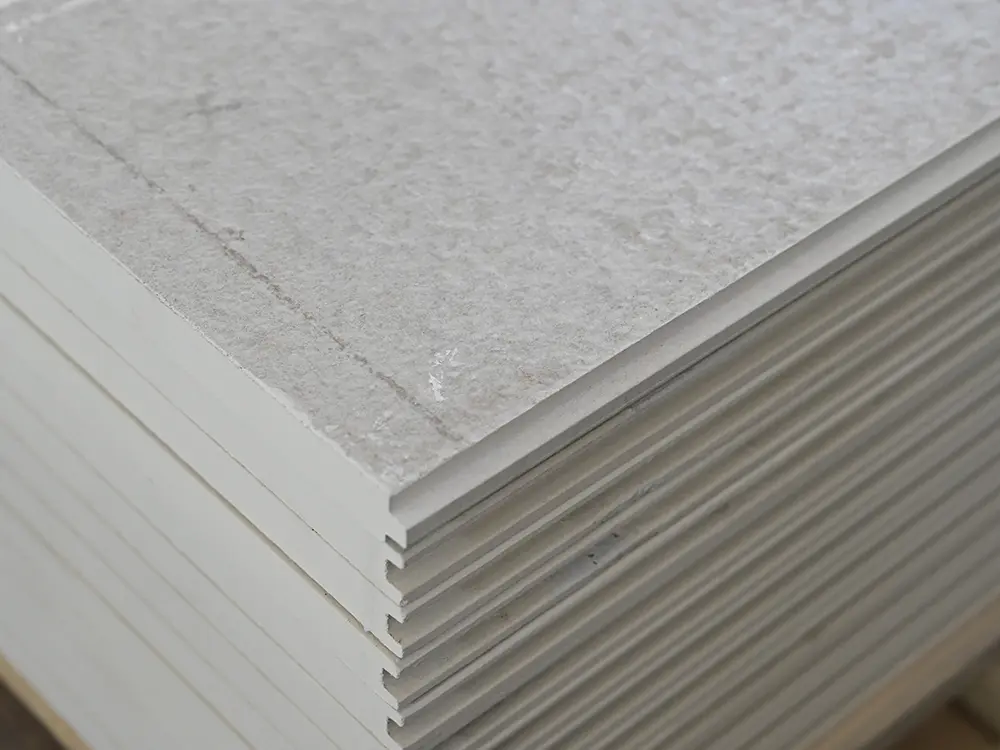

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel

The fiber cement industry is undergoing significant transformations, driven by

The fiber cement industry is undergoing significant transformations, driven by

Evaluating supplier reliability is crucial for businesses looking to source top-quality fiber cement partition boards. The process involves thorough assessment of key factors such as

Evaluating supplier reliability is crucial for businesses looking to source top-quality fiber cement partition boards. The process involves thorough assessment of key factors such as