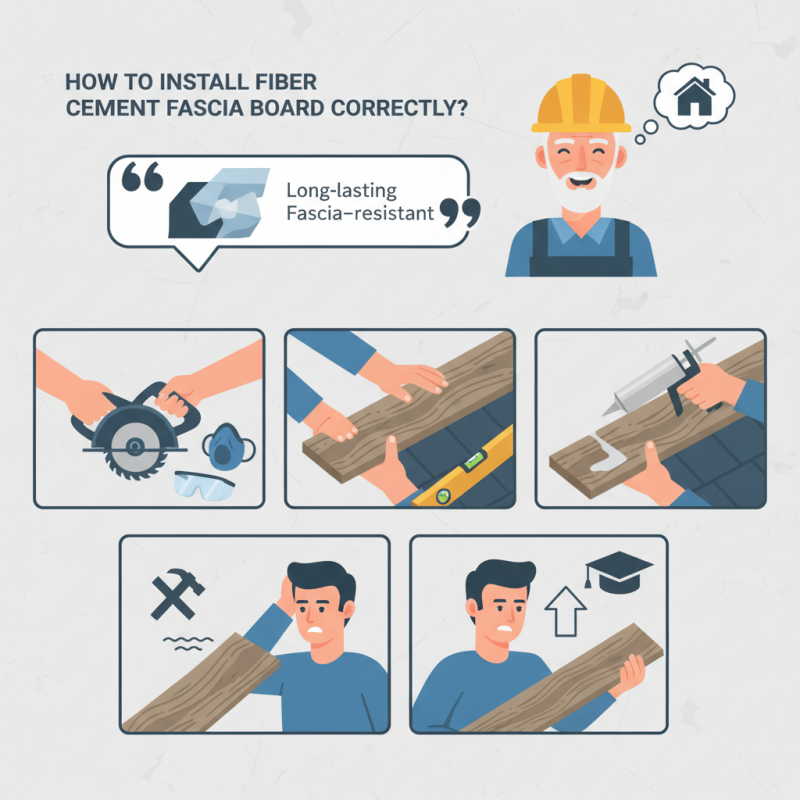

How to Install Fiber Cement Fascia Board Correctly?

Installing Fiber Cement Fascia Board can seem daunting. However, with the right guidance, this task becomes achievable. Mike Lewis, a well-known expert in building materials, once said, "Proper installation ensures the longevity of fiber cement products." His insight highlights the significance of careful installation.

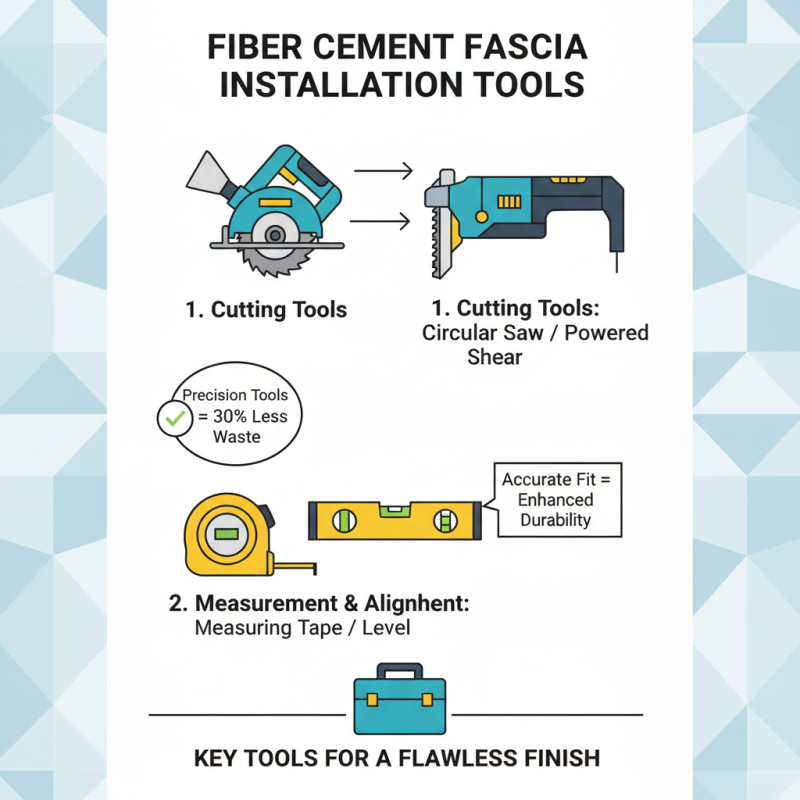

Choosing the right tools is vital. You need a saw specifically designed for fiber cement and protective gear. Working meticulously helps prevent common mistakes. Many homeowners rush, leading to misalignment or insufficient sealing.

Remember, even seasoned installers face challenges. Encountering warped boards or inconsistent cuts is not uncommon. Reflecting on these experiences can help improve your technique. Embrace the learning process. Each project with Fiber Cement Fascia Board offers a chance to grow in skill and confidence.

Understanding Fiber Cement Fascia Board: Materials and Benefits

Fiber cement fascia board is gaining popularity due to its durability and aesthetic appeal. This material consists of a combination of sand, cement, and cellulose fibers. It withstands harsh weather better than traditional wood options. Reports indicate that fiber cement can last up to 50 years with minimal maintenance. These boards resist rot, insects, and fire, making them suitable for various climates.

Moreover, the energy efficiency of fiber cement is notable. It helps regulate household temperatures, potentially reducing energy bills. A DOE study found that homes using fiber cement siding can save approximately 25% on cooling costs. However, installation requires attention to detail. Improper sealing can lead to moisture accumulation and damage over time. This material is also heavier than alternatives, making it trickier to handle during installation.

Aesthetically, fiber cement can mimic the look of wood, giving homeowners flexibility in design. It comes in various colors and finishes, allowing for broad creative expression. Still, some users may find the texture differs from expected wood grain. It's essential to review samples before making a decision. Despite its advantages, potential buyers should weigh these factors against their needs and budget.

Step-by-Step Installation Process for Fiber Cement Fascia Board

Installing fiber cement fascia board requires attention to detail and correct techniques. Begin by measuring the fascia area precisely. Proper measurements prevent waste and ensure a perfect fit. Use a circular saw with a fiber cement blade for accurate cuts. Remember to wear protective gear, as dust can be hazardous.

Next, prepare the surface for installation. Ensure it is clean and dry. If the existing fascia board is damaged, remove it. Place the fiber cement board against the surface, ensuring it's level and aligned. It’s crucial to secure the board with corrosion-resistant fasteners, providing durability against the elements. Reports show that properly installed fiber cement can last over 50 years, making it a wise choice.

Tips: Always work with a partner. It’s easier to hold and align materials. When cutting, regularly check your measurements to prevent errors. Reflect on your installation process. Have you overlooked any details? Continuous improvement is essential for better results.

Best Practices for Sealing and Finishing Fiber Cement Fascia

When installing fiber cement fascia board, sealing and finishing are critical. Proper sealing prevents water infiltration. Water damage is a leading cause of structural issues. According to industry reports, homes with unsealed fascia often suffer from moisture-related problems, leading to costly repairs. It’s essential to apply a high-quality sealant that adheres well to fiber cement materials.

Pay attention to finishing techniques as well. Use a smooth, even application of paint or stain for durability. A report from the Fiber Cement Association indicates that well-finished fascia can last up to 50 years. However, poorly finished surfaces may need frequent touch-ups. This can add to long-term maintenance costs. Inadequate finishing often leads to peeling and chalking, which are signs of an insufficient seal.

Regular inspection is vital. Homeowners should check for any signs of wear or damage after severe weather. Trapped moisture under poorly sealed boards can cause deterioration. Remember, taking these steps may require some trial and error. Not every installation will be perfect. Evaluating past projects can provide insight into better methods. Invest time in proper sealing and finishing to enhance the longevity of your fiber cement fascia board.

How to Install Fiber Cement Fascia Board Correctly? - Best Practices for Sealing and Finishing Fiber Cement Fascia

| Step |

Description |

Materials Needed |

Best Practices |

| 1 |

Measure and cut the fascia board to required lengths. |

Fiber cement board, saw, measuring tape |

Ensure accurate measurements for a snug fit. |

| 2 |

Install the fascia board using appropriate fasteners. |

Fasteners, drill/screwdriver |

Use corrosion-resistant fasteners for durability. |

| 3 |

Seal joints and edges with caulk or sealant. |

Caulk, caulking gun |

Choose a high-quality exterior-grade sealant. |

| 4 |

Finish with paint or primer to protect the fascia. |

Exterior paint/primer, brush/roller |

Apply at least two coats for better protection. |

Maintenance Tips for Longevity of Fiber Cement Fascia Boards

Fiber cement fascia boards are durable and stylish, but they require proper maintenance. Regular inspection is key. Look for signs of damage or wear. Small cracks can become larger issues if ignored. Cleaning these boards helps prevent dirt accumulation. Use mild soap and water for this task. Avoid harsh chemicals, as they can harm the material.

Paint can enhance their appearance. However, not all paints are suitable. Choose ones specifically designed for fiber cement. Over time, the paint may fade and require reapplication. Inspect the painted surfaces at least once a year. Don't neglect the caulking around the seams. Ensure it remains intact to prevent water infiltration.

Proper installation is also crucial for longevity. Gaps and misalignment can lead to issues down the road. When the weather changes, fiber cement can expand and contract. Ensure it is not too tightly fastened. Leave space for natural movement. These minor details can prevent costly repairs later on. Regular attention to your fascia boards will enhance their lifespan significantly.

Products

About Us

Download

News

Blog

Contact Us

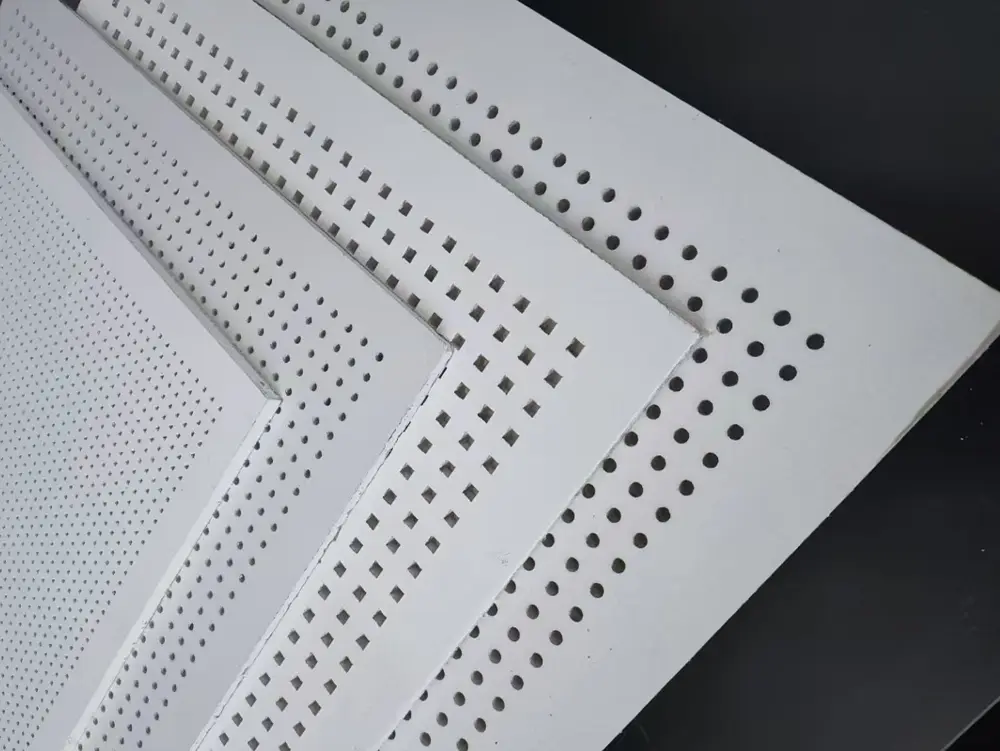

LEAO®Deco Ceiling

LEAO®Deco Ceiling LEAO® Perforated Ceiling

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel