Mastering the Use of Calcium Silicate Board: Innovative Techniques for Success

In recent years, the construction and building materials industry has seen a significant shift towards the adoption of innovative materials, with Calcium Silicate Board (CSB) emerging as a critical player in this transformation.

According to a report by MarketsandMarkets, the global calcium silicate board market is projected to reach USD 2.8 billion by 2025, driven by the need for lightweight, fire-resistant, and environmentally friendly solutions in various construction applications.

Featuring superior thermal insulation and moisture resistance, CSB is not only favored for its practical benefits but also for its versatility in design, making it suitable for both commercial and residential projects.

As industry professionals seek to master the use of Calcium Silicate Board, understanding advanced techniques and innovative applications becomes essential for success in a competitive market.

This blog will delve into the effective strategies and creative uses of CSB to help industry stakeholders capitalize on its numerous advantages.

Understanding Calcium Silicate Board: Composition and Properties

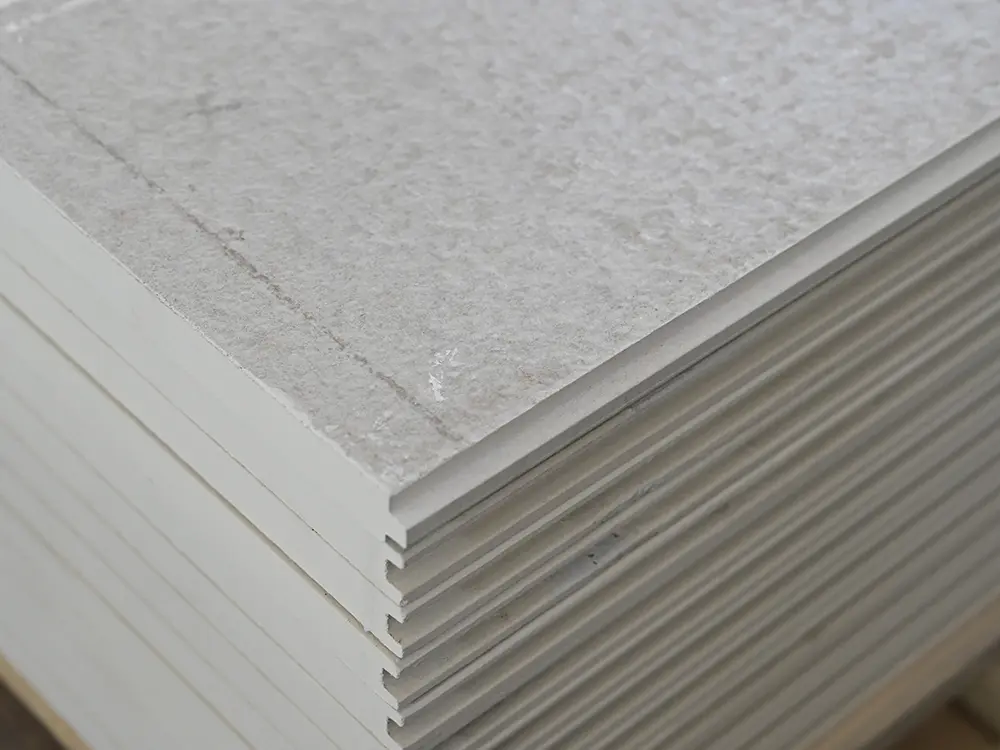

Calcium silicate board has gained significant attention in the construction industry due to its unique composition and properties. This innovative material is primarily composed of silica and lime, combined with reinforcing fibers that enhance its durability. According to a report by Freedonia Group, the demand for calcium silicate board is expected to grow by 4.5% annually through 2026, driven by its application in fire-resistant and energy-efficient building materials. The board's ability to withstand high temperatures makes it a preferred choice for non-combustible applications, aligning with increased safety regulations in the construction sector.

One of the standout properties of calcium silicate board is its exceptional moisture resistance. Industry studies indicate that this material can maintain structural integrity in humid environments, making it ideal for areas like bathrooms and kitchens. The Thermal Performance of Building Materials report highlights that calcium silicate board offers a low thermal conductivity, which aids in energy efficiency and can lead to substantial cost savings for building owners. With these intrinsic qualities, the calcium silicate board is not only an innovative alternative to traditional building materials but also a sustainable option that supports modern architectural needs.

Mastering the Use of Calcium Silicate Board: Properties and Applications

This chart illustrates the different properties of calcium silicate board compared to traditional materials, highlighting their advantages in various applications.

Innovative Installation Techniques for Enhanced Durability and Performance

Calcium silicate board has gained popularity in construction due to its remarkable durability and versatility. To maximize its performance, adopting innovative installation techniques is crucial. One effective method is using a staggered joint pattern during installation. This technique not only enhances the structural integrity but also minimizes the chances of cracking and water penetration. By offsetting the joints, you create a more robust surface that can withstand environmental stressors.

Calcium silicate board has gained popularity in construction due to its remarkable durability and versatility. To maximize its performance, adopting innovative installation techniques is crucial. One effective method is using a staggered joint pattern during installation. This technique not only enhances the structural integrity but also minimizes the chances of cracking and water penetration. By offsetting the joints, you create a more robust surface that can withstand environmental stressors.

Another important tip for successful installation is ensuring proper sealing of joints. Utilizing high-quality sealants, such as silicone-based products, can provide an additional layer of protection against moisture. This is particularly beneficial in areas prone to high humidity, where maintaining the integrity of the board is essential. Additionally, applying sealants helps to reduce sound transmission, thereby enhancing acoustic performance.

Lastly, consider the underlying substrate when installing calcium silicate boards. A well-prepared framework will facilitate better adhesion and overall stability. Make sure the surface is clean, dry, and structurally sound before installation. With these innovative techniques and attention to detail, your calcium silicate board installations will achieve enhanced durability and performance, ensuring long-lasting results.

Creative Applications of Calcium Silicate Board in Modern Architecture

Calcium silicate board has emerged as a popular material in modern architecture, offering innovative solutions that blend functionality with aesthetic appeal. Its use in the construction of contemporary buildings showcases not only its durability and fire-resistant properties but also its potential for creative design. Architects are increasingly experimenting with calcium silicate board, utilizing it in various applications such as decorative wall panels, ceiling elements, and insulation systems, allowing for enhanced energy efficiency without compromising on style.

A prime example of such creativity is evident in the recent architectural developments around Santa Clara University, where new facilities aim to inspire innovation and collaboration. The dedication of the John A. and Susan Sobrato Campus for Discovery and Innovation highlights how modern educational spaces can incorporate versatile materials like calcium silicate board to create dynamic environments. Furthermore, the Gurdwara of San Jose serves as a remarkable reminder of the potential for cultural and community spaces to utilize innovative materials, showcasing how architectural heritage can be preserved while embracing modern techniques and technologies.

Through these applications, calcium silicate board not only meets practical needs but also enriches the visual and functional landscape of modern architecture.

Maintenance Tips and Best Practices for Longevity of Calcium Silicate Boards

When it comes to ensuring the longevity of calcium silicate boards, implementing effective maintenance tips is essential. One of the most crucial aspects is keeping the boards free from moisture and contaminants that can compromise their structural integrity. Regular inspections should be conducted to identify any signs of damage or wear. If any sections reveal cracks or water infiltration, immediate repairs should be carried out to prevent further deterioration. Additionally, ensure that the boards are sealed correctly during installation to provide an extra layer of protection against moisture and environmental factors.

Another best practice for maintaining calcium silicate boards involves using appropriate cleaning methods. It is advisable to use mild detergents and avoid abrasive tools that can scratch the surface. For routine cleaning, a damp cloth is often sufficient to keep the boards looking fresh. Furthermore, it is vital to ensure proper ventilation in areas where these boards are installed, as good airflow helps to minimize potential humidity buildup, thus extending the lifespan of the material. Incorporating these maintenance strategies not only enhances the durability of calcium silicate boards but also preserves their aesthetic appeal over time.

Mastering the Use of Calcium Silicate Board: Innovative Techniques for Success

| Technique |

Description |

Maintenance Tips |

Best Practices |

| Installation Techniques |

Ensure proper spacing and sealing of joints for durability. |

Regularly inspect joints for wear and tear. |

Follow manufacturer instructions closely for installation. |

| Surface Coating |

Apply a protective coating to enhance moisture resistance. |

Reapply protective coating annually. |

Choose eco-friendly coatings to reduce environmental impact. |

| Cleaning Protocols |

Use non-abrasive cleaners to maintain surface integrity. |

Dust surfaces regularly to prevent buildup. |

Incorporate cleaning in routine maintenance schedules. |

| Temperature Control |

Maintain stable temperatures to prevent expansion and contraction. |

Monitor indoor humidity levels. |

Utilize HVAC systems for optimal climate control. |

| Repair Techniques |

Patch small cracks promptly to avoid larger damages. |

Inspect for damages after seasonal changes. |

Use manufacturer-recommended repair materials. |

Troubleshooting Common Issues with Calcium Silicate Board Projects

When working with calcium silicate boards, troubleshooting common issues is essential for successful project execution. Despite their benefits, users often encounter challenges such as improper installation or moisture infiltration. According to industry reports, improper handling can lead to significant effects on durability and performance, often resulting in costly repairs and delays. Understanding the physical properties of calcium silicate boards, such as their moisture resistance and thermal insulation capabilities, is key to addressing these issues effectively.

Recent trends reveal divergent price movements in the calcium silicate market, highlighting the impact of supply chain dynamics on project budgeting. For instance, in June 2025, prices fell in China due to oversupply and weak demand, while Germany saw a rise in costs attributed to expensive imports. Such fluctuations can influence project planning and material selection strategies. By staying informed about market trends and addressing common installation pitfalls, construction professionals can enhance their project outcomes and mitigate risks associated with calcium silicate boards.

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

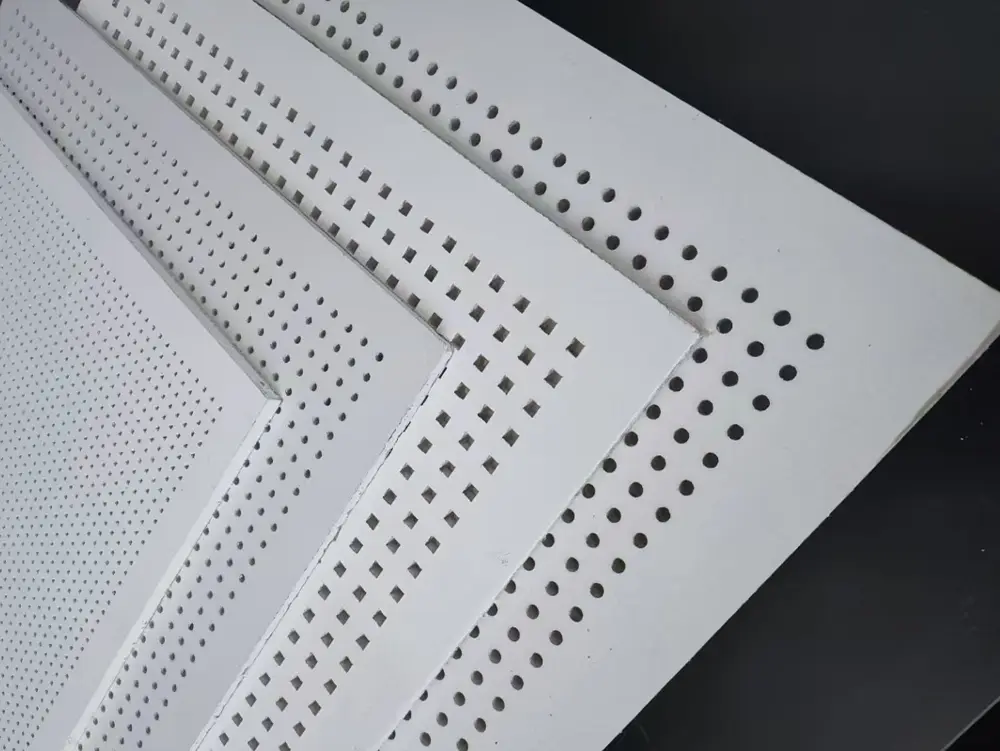

LEAO®Deco Ceiling LEAO® Perforated Ceiling

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel

Calcium silicate board has gained popularity in construction due to its remarkable durability and versatility. To maximize its performance, adopting innovative installation techniques is crucial. One effective method is using a staggered joint pattern during installation. This technique not only enhances the structural integrity but also minimizes the chances of cracking and water penetration. By offsetting the joints, you create a more robust surface that can withstand environmental stressors.

Calcium silicate board has gained popularity in construction due to its remarkable durability and versatility. To maximize its performance, adopting innovative installation techniques is crucial. One effective method is using a staggered joint pattern during installation. This technique not only enhances the structural integrity but also minimizes the chances of cracking and water penetration. By offsetting the joints, you create a more robust surface that can withstand environmental stressors.