Top 10 Tips for Using Fiber Cement Board Effectively?

Fiber Cement Board has become a popular choice for builders and architects. This material combines the durability of cement with the flexibility of fiber. Experts like John Smith, a noted construction specialist, have highlighted the significance of this trend. He once stated, "Fiber Cement Board offers unmatched resilience and versatility for modern construction."

Choosing the right method to use Fiber Cement Board can be challenging. It requires attention to details often overlooked. Many professionals recommend preparing the surface thoroughly before installation. Proper sealing and spacing are essential to prevent moisture damage. Ignoring these steps can lead to costly repairs later on.

Additionally, integrating Fiber Cement Board into designs requires creativity. The aesthetic potential is vast, yet many folks fall into routine applications. Experimenting with textures and colors can yield stunning results. But it's crucial to embrace feedback and iterate on designs to achieve the best outcome. This approach ensures that Fiber Cement Board truly shines in any project.

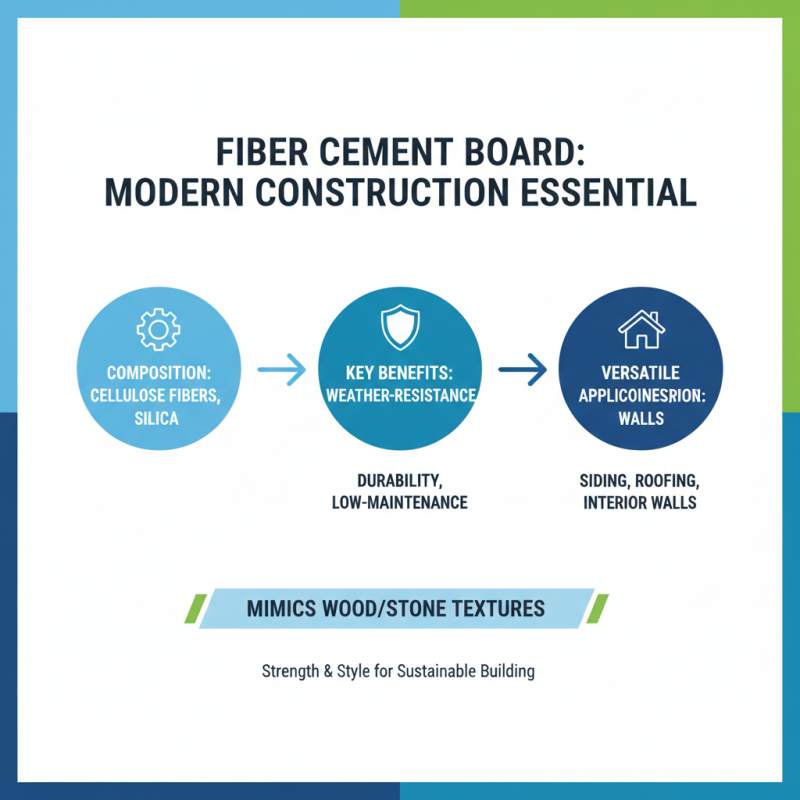

Understanding Fiber Cement Board and Its Applications

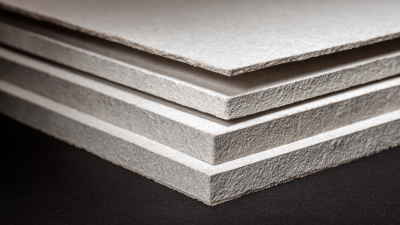

Fiber cement board has become a popular choice in modern construction. It’s made from a mixture of cement, cellulose fibers, and fine silica. This combination gives the board incredible durability and resistance to various weather conditions. Many buildings use fiber cement boards for siding, roofing, and even as interior walls. They can mimic the appearance of wood or stone without the maintenance drawbacks.

Applications of fiber cement board are vast. Homeowners enjoy its versatility for both aesthetic and practical purposes. It’s suitable for high-humidity areas like bathrooms and kitchens. However, installing fiber cement board can be a challenge. Precise measurements are necessary to avoid fit issues. Improper cutting can lead to wasted materials. Even with its advantages, one must consider installation costs and potential difficulties. It’s essential to weigh these aspects before deciding on its use. Overall, understanding the material is vital for effective and successful implementation.

Choosing the Right Tools and Materials for Installation

When working with fiber cement board, choosing the right tools and materials is crucial for a successful installation. Quality cutting tools can significantly affect the precision of your cuts. A standard circular saw or a score-and-snap cutter can work well, but sometimes they don't provide the cleanest edges. Consider a specialized fiber cement saw blade. It can make a noticeable difference, even if it's not always necessary.

Don't overlook the importance of protective gear. The dust generated can be harmful. A well-fitted mask and safety goggles are essential. It’s easy to underestimate this, but taking the time to protect yourself is vital. Skipping this step may seem minor, but it can lead to health concerns.

Choosing the correct fasteners is another key component. Not all screws and nails work well with fiber cement. Some may rust or fail over time. Always opt for corrosion-resistant options to maintain longevity. It’s a detail that can easily be ignored but will impact the durability of your installation. This oversight can be frustrating later on. Pay attention to these details for better results.

Top 10 Tips for Using Fiber Cement Board Effectively

| Tip # |

Tip Description |

Recommended Tool |

Safety Equipment |

| 1 |

Choose the right fiber cement board thickness for your project. |

Circular Saw |

Safety Glasses |

| 2 |

Use a carbide-tipped saw blade for clean cuts. |

Carbide-Tipped Blade |

Dust Mask |

| 3 |

Make sure to mark and measure accurately before cutting. |

Measuring Tape |

None |

| 4 |

Pre-drill holes for screws to minimize splitting. |

Drill |

Work Gloves |

| 5 |

Leave gaps for expansion and contraction. |

Level |

None |

| 6 |

Seal all joints and edges with appropriate sealant. |

Caulking Gun |

None |

| 7 |

Use the correct fasteners for your installation. |

Screws |

None |

| 8 |

Install a water-resistant barrier behind the boards. |

Moisture Barrier |

None |

| 9 |

Regularly check for signs of damage or wear. |

Inspection Tools |

Safety Gloves |

| 10 |

Follow manufacturer guidelines for installation. |

Installation Manual |

None |

Step-by-Step Installation Process of Fiber Cement Board

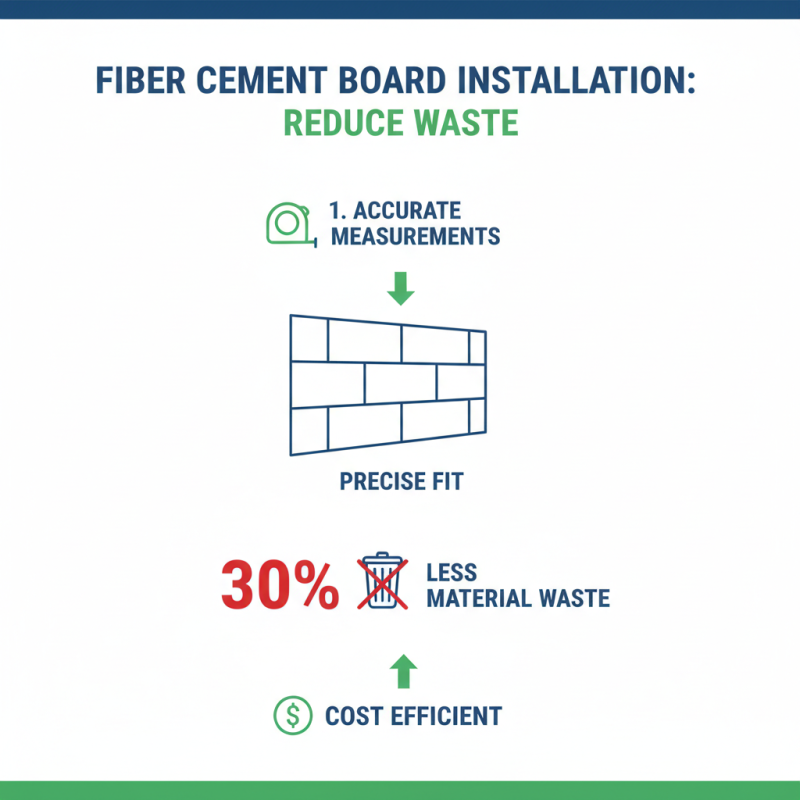

Installing fiber cement board requires careful planning. The process typically starts with measuring the area. Accurate measurements are crucial. The board must fit precisely to avoid gaps. An industry report states that improper installation can lead to 30% more material waste, which affects cost efficiency.

Cut the boards using a circular saw. Ensure that you wear safety goggles and a mask. The dust generated can be harmful. Many overlook this safety step, resulting in health issues. Then, apply a proper underlayment. This adds moisture protection. Studies show that without it, the longevity of the installation may decrease by 20%.

Align the boards correctly. Use a level to check your work. Misalignment can complicate the final finish. Fasten them properly, using the right screws. Skipping this may lead to movement over time. Finally, caulk any seams. This helps prevent water intrusion. While it may seem like a simple task, attention to detail is critical for durability.

Maintaining and Caring for Fiber Cement Board

Caring for fiber cement board requires attention to detail. Regular maintenance extends its life. One tip is to clean the surface at least twice a year. Use a soft brush and mild detergent. This simple action prevents dirt buildup. However, avoid abrasive cleaners. They can scratch the surface.

Another important step is inspecting for damage. Look for cracks or holes. Addressing these issues promptly can prevent larger problems. Use a patching compound made for fiber cement. It may take time to perfect your technique. Practice makes better!

Lastly, keeping the edges sealed is crucial. This helps protect against moisture. Apply a quality sealant to all exposed edges. Even a small oversight can lead to issues later. Maintaining fiber cement board can feel overwhelming. But with regular care, you’ll keep it looking fresh and functional.

Common Mistakes to Avoid When Using Fiber Cement Board

When working with fiber cement board, avoiding common mistakes can save time and resources. Many users underestimate the importance of proper installation methods. For instance, not leaving gaps for expansion can lead to buckling and warping. This mistake often arises from rushing the project. Adequate planning and foresight can prevent these costly errors.

One key tip is to ensure your cutting tools are sharp. Dull tools can create jagged edges, making installation difficult. It's essential not to push the material too hard against the blades. Instead, take your time to achieve clean cuts. This approach helps in fitting the pieces together more seamlessly.

Another frequent mistake is neglecting to seal the joints properly. Skipping this step can result in moisture seeping into the board, causing long-term damage. Applying high-quality sealant at the joints is crucial. Additionally, consider using a primer before painting to improve adhesion. It’s easy to overlook these details in the excitement of beginning the project. Always double-check your work to avoid regrets later on.

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

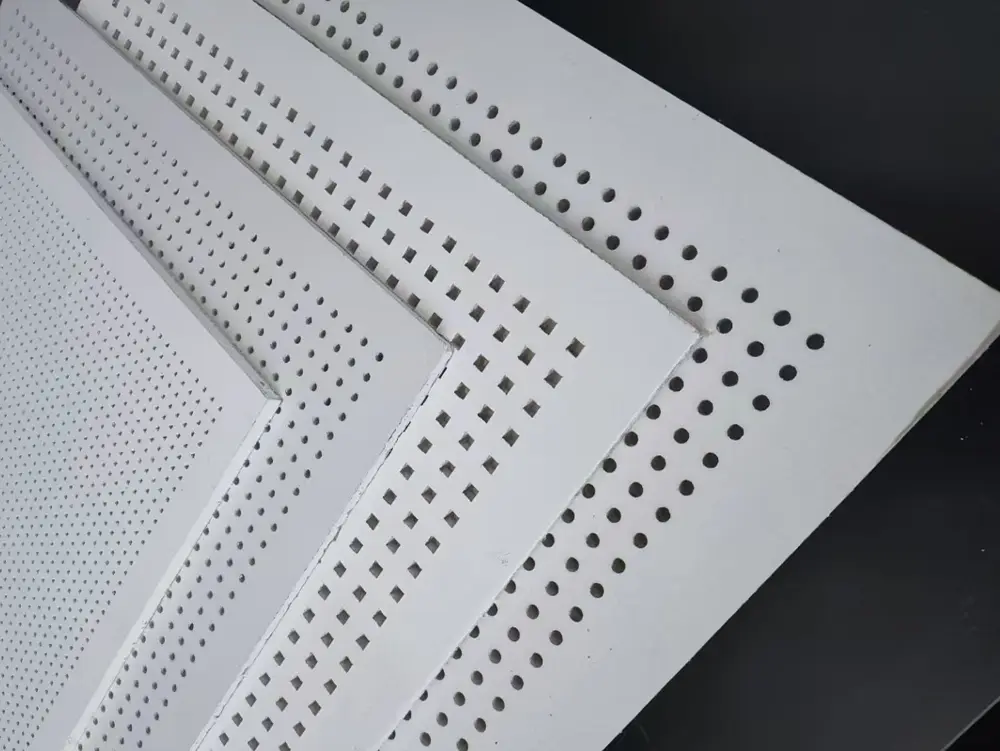

LEAO®Deco Ceiling LEAO® Perforated Ceiling

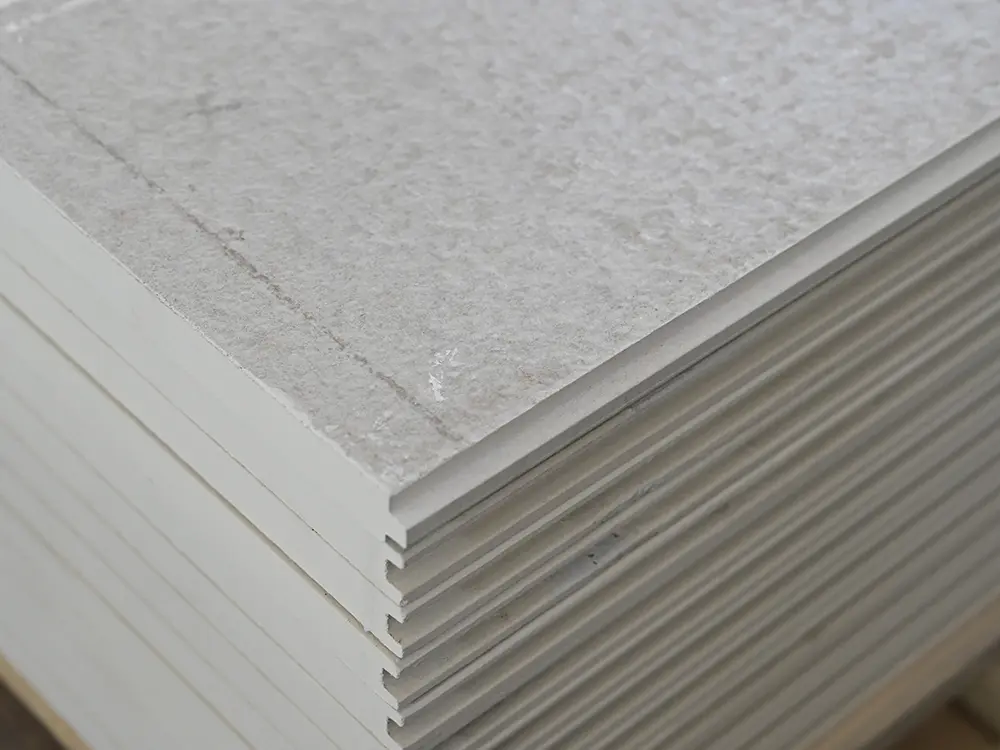

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel