Top Trends in Digital Print Boards for 2025 What You Need to Know

As we approach 2025, the landscape of Digital Print Boards is poised for significant transformation, driven by technological innovations and evolving consumer demands. According to a recent report from Smithers Pira, the digital print market is projected to grow from $21 billion in 2020 to $30 billion by 2025, representing a compound annual growth rate (CAGR) of 8.5%. This growth underscores the increasing adoption of Digital Print Boards across various sectors, including packaging, signage, and promotional materials.

Industry expert Dr. Emily Carter, a recognized authority in the field of digital printing, emphasizes the shift towards more sustainable and cost-effective solutions. She notes, "The future of Digital Print Boards lies in their ability to integrate advanced printing technologies with eco-friendly materials, meeting both business and environmental needs." As digital print technology continues to advance, key trends such as personalization, automation, and the integration of artificial intelligence are expected to redefine the functionalities and applications of Digital Print Boards, paving the way for a more dynamic and responsive printing industry.

With these trends on the horizon, stakeholders in the industry must remain vigilant and adaptable to leverage the unfolding opportunities. The implications for manufacturing processes, market strategies, and customer engagement are profound, heralding a new era for Digital Print Boards by 2025.

Emerging Technologies in Digital Print Boards for 2025

As we approach 2025, the landscape of digital print boards is set to undergo significant transformation driven by emerging technologies. One of the key innovations is the advancement in inkjet technology, which offers higher resolution and faster printing speeds. This improvement not only enhances print quality but also allows for the production of complex designs that were previously difficult or impossible to achieve. Additionally, the integration of artificial intelligence in the printing process is enabling more efficient workflow management, allowing operators to streamline operations and reduce waste.

Tips: To stay ahead in the competitive digital print market, consider investing in training programs for your staff on the latest digital technologies. Embracing these innovations can facilitate smoother transitions to upgraded systems and improve overall productivity.

Another crucial trend is the move towards sustainable practices. As environmental concerns become increasingly paramount, manufacturers are focusing on eco-friendly printing solutions. This includes the use of biodegradable inks and recyclable substrates, which not only appeal to environmentally conscious consumers but also comply with growing regulations in various regions. Adapting to these sustainable practices not only helps the planet but can also position your business as a leader in socially responsible manufacturing.

Tips: When exploring sustainable options, evaluate your supplier's practices and materials to ensure they meet your environmental standards. Building partnerships with eco-conscious suppliers can enhance your brand's reputation and attract a broader customer base.

Top Trends in Digital Print Boards for 2025

| Trend |

Description |

Impact on Industry |

Expected Growth Rate |

| Sustainability |

Increased focus on eco-friendly materials and processes in printing. |

Higher demand for sustainable products, redefining supply chain practices. |

15% |

| Automation |

Integration of AI and machine learning for optimized printing processes. |

Increased efficiency and reduced human error. |

20% |

| Customization |

Rising demand for personalized print products tailored to customer preferences. |

Enhanced customer engagement and satisfaction. |

18% |

| Digital Textile Printing |

Growth in digital printing technologies applied to textiles. |

Expansion of markets such as fashion and interior design. |

25% |

| Smart Packaging |

Integration of technology into packaging to enhance consumer interaction. |

New marketing opportunities and improved product tracking. |

22% |

Sustainability Trends in Digital Printing Materials and Processes

As we approach 2025, sustainability is set to play a pivotal role in the digital printing industry, influencing both materials and processes. The shift towards eco-friendly practices is not merely a trend but a necessary evolution driven by environmental concerns and consumer demand for greener alternatives. Manufacturers are increasingly adopting biodegradable inks and recyclable substrates, paving the way for a circular economy in digital printing. These innovations reduce waste and energy consumption, ensuring that products maintain high-quality standards while minimizing their ecological footprint.

In addition to materials, there is a growing emphasis on sustainable processes in digital printing. Technologies such as water-based inks and energy-efficient printing solutions are becoming more prevalent, reducing harmful emissions and resource use. Furthermore, advancements in digital printing techniques allow for on-demand production, which minimizes excess inventory and waste. As businesses prioritize sustainability, the adoption of these practices not only enhances brand reputation but also aligns with consumers' values, leading to stronger market positioning. Thus, sustainability in digital printing is not just a component of the process; it is integral to the industry's future trajectory.

Customization and Personalization in Digital Print Boards

In the evolving landscape of digital print boards, customization and personalization are emerging as essential trends for 2025. Consumers are increasingly seeking unique products that reflect their individual tastes and preferences. This shift is driving digital print providers to offer tailored solutions that can cater to specific customer requirements. From custom designs to personalized messages, the ability to create one-of-a-kind items sets businesses apart in a competitive market.

For those looking to leverage this trend, here are some tips: First, gather insights into your target audience’s preferences. Use surveys or social media interactions to understand what designs or themes resonate most. Secondly, invest in user-friendly design tools that allow customers to create or modify their own print boards easily. Providing templates or inspirational designs can also help spark creativity while making the process accessible.

Furthermore, staying ahead of design trends will enhance your offerings. Regularly analyze market developments and emerging styles to refresh your product line. By embracing customization and personalization, businesses can foster a deeper connection with their customers, ultimately driving loyalty and sales.

Integration of AI and Automation in Digital Printing Solutions

The integration of AI and automation in digital printing solutions is set to revolutionize the industry by 2025. As digital print boards evolve, businesses are increasingly adopting AI algorithms to enhance production efficiency and quality. These advanced technologies allow for real-time data analysis, enabling printers to optimize their workflow, manage their resources effectively, and reduce waste. By harnessing AI, companies can predict maintenance needs, ensuring that equipment operates at peak performance, ultimately leading to reduced downtime and cost savings.

Automation complements AI in transforming digital printing processes. Automated systems can handle repetitive tasks such as pre-press preparation and post-production finishing, freeing up human operators to focus on more complex, value-added activities. Furthermore, the integration of smart sensors and IoT technologies in printing machinery enables remote monitoring and diagnostics. This ensures that any issues can be resolved swiftly, minimizing disruptions in the printing process. As these digital print boards become more intelligent and interconnected, they will pave the way for a more agile and responsive printing environment, which is crucial in meeting the ever-increasing demands of personalization and rapid turnaround times in the market.

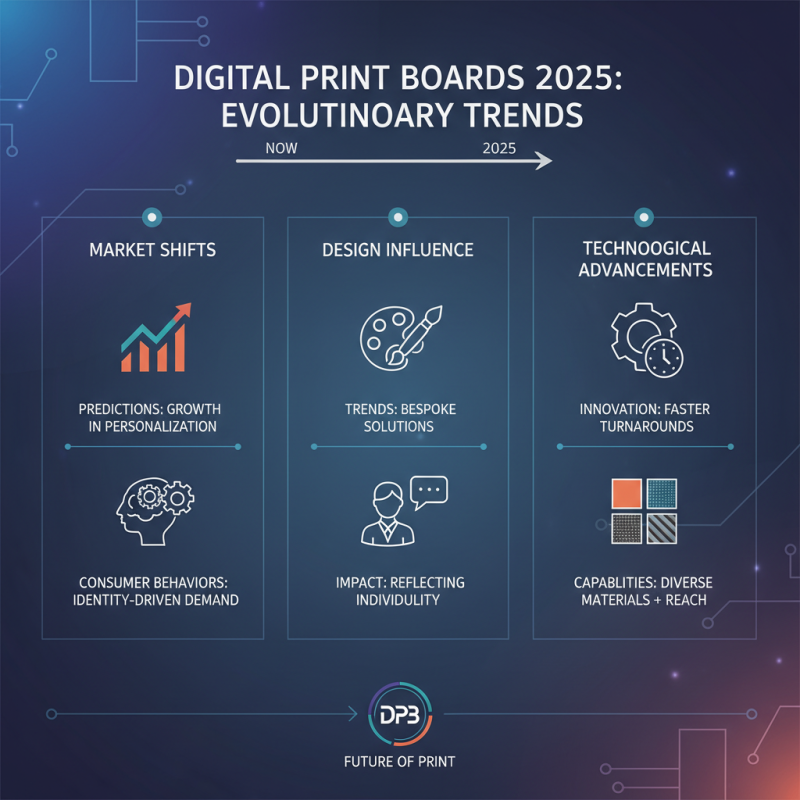

Top Trends in Digital Print Boards for 2025

This chart illustrates the key trends in digital print boards for 2025, highlighting the integration of AI and automation in digital printing solutions. The data reflects the anticipated percentage of implementation of these technologies across various sectors.

Market Predictions and Consumer Behaviors Influencing Digital Print Boards

As we move towards 2025, understanding the interplay between market predictions and consumer behaviors will be crucial for the evolution of digital print boards. The rise in personalization and customization demands will significantly influence design trends. Consumers now seek products that reflect their individual identities and preferences, pushing brands to adopt more flexible and innovative printing techniques. This shift towards bespoke solutions is likely to drive advancements in technology that allow for quicker turnarounds and diverse material compatibility, thus broadening the market's reach.

Another key factor is the increasing focus on sustainability. Consumers are becoming more environmentally conscious, prompting them to favor products made from eco-friendly materials and processes. This trend is expected to shape the development of digital print boards, leading to the adoption of sustainable practices across the supply chain. Brands will need to communicate their commitment to sustainability clearly, as this can significantly affect purchasing decisions. Paying attention to these emerging behaviors will be essential for companies aiming to stay competitive in the digital print landscape.

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

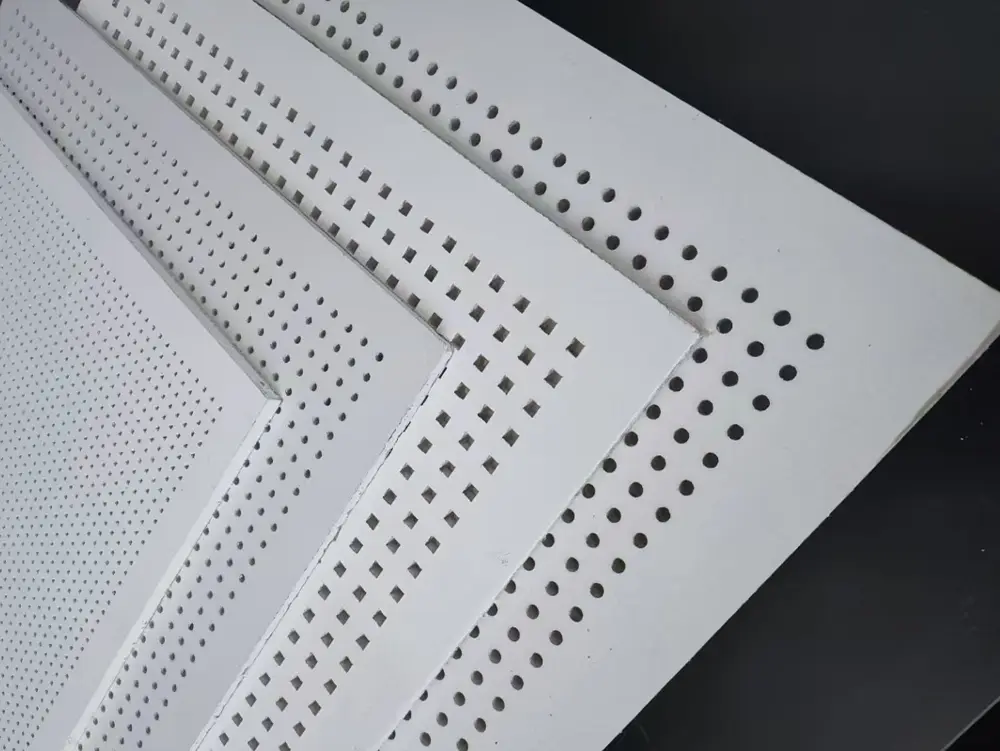

LEAO®Deco Ceiling LEAO® Perforated Ceiling

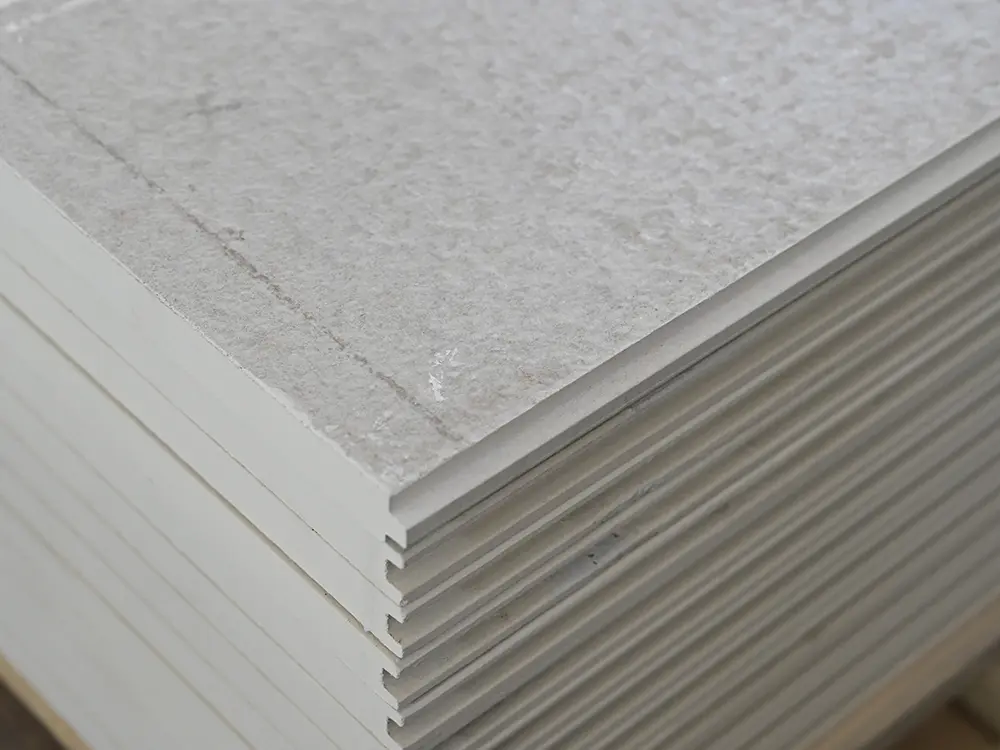

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel