The Ultimate Guide to Choosing the Right Fiber Cement Backer Board for Your Projects

In the realm of construction and home improvement, selecting the appropriate materials is crucial for ensuring durability and long-lasting performance. Among these materials, the Fiber Cement Backer Board has emerged as a preferred choice for many professionals and DIY enthusiasts alike. According to the National Association of Home Builders (NAHB), the demand for fiber cement products has surged by approximately 25% over the last decade, owing to their superior resistance to moisture, mold, and fire. Additionally, a report from MarketsandMarkets projects that the global fiber cement market will reach USD 22.5 billion by 2026, highlighting its growing relevance in both residential and commercial projects. This guide aims to navigate the various benefits and types of Fiber Cement Backer Board available, helping you make informed decisions for your upcoming projects.

In the realm of construction and home improvement, selecting the appropriate materials is crucial for ensuring durability and long-lasting performance. Among these materials, the Fiber Cement Backer Board has emerged as a preferred choice for many professionals and DIY enthusiasts alike. According to the National Association of Home Builders (NAHB), the demand for fiber cement products has surged by approximately 25% over the last decade, owing to their superior resistance to moisture, mold, and fire. Additionally, a report from MarketsandMarkets projects that the global fiber cement market will reach USD 22.5 billion by 2026, highlighting its growing relevance in both residential and commercial projects. This guide aims to navigate the various benefits and types of Fiber Cement Backer Board available, helping you make informed decisions for your upcoming projects.

Understanding Fiber Cement Backer Board: Types and Benefits

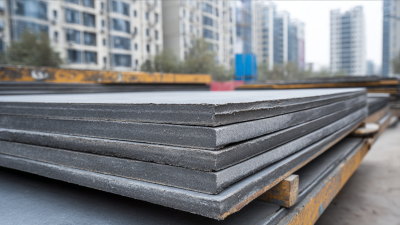

When embarking on home improvement projects, understanding the various types and benefits of fiber cement backer board is crucial. This versatile material is known for its durability, resistance to moisture, and fireproof properties, making it an excellent choice for areas prone to water exposure, such as bathrooms or kitchens. The two primary types of fiber cement backer boards are standard and high-density, each offering distinct advantages. Standard backer board is typically lighter and easier to handle, while high-density boards provide superior strength and moisture resistance.

Tips: When selecting a fiber cement backer board, always check the product specifications to ensure it meets your project needs. Additionally, consider the installation environment; for wet areas, high-density boards may be the preferable option due to their enhanced moisture resistance.

Another benefit of using fiber cement backer board is its compatibility with various tile types, allowing for a seamless finish. Ensure that your choice aligns with the kind of tile you plan to use, whether it’s ceramic, porcelain, or stone.

Tips: Don't forget to use appropriate tools during installation, such as a carbide-tipped saw blade, to avoid damaging the board and ensure a clean cut.

Key Features to Consider When Choosing Fiber Cement Backer Board

When selecting fiber cement backer board for your projects, it's crucial to focus on key features that enhance performance and sustainability. One significant factor to consider is moisture resistance. Industry reports indicate that fiber cement boards outperform traditional materials in moisture-related issues, making them ideal for high-humidity areas like bathrooms and kitchens. With a combination of cement, sand, and cellulose fibers, these boards not only resist warping and buckling but also maintain their integrity over time, which is essential for durability.

Another vital aspect is the board's ease of installation. Heavy-duty fiber cement backer boards are designed to be lightweight and easy to handle, reducing labor costs and installation time. A study revealed that projects utilizing fiber cement material experience up to 30% faster installation rates compared to conventional materials. Additionally, the eco-friendly benefits of fiber cement are noteworthy, contributing to sustainable building practices by using non-toxic ingredients and reducing waste in the manufacturing process. This makes it a favored choice among environmentally conscious builders and homeowners looking to make informed decisions for their siding and backer board needs.

Comparing Different Brands of Fiber Cement Backer Board

When it comes to selecting the right fiber cement backer board for your project, understanding the available brands is crucial. Each brand offers unique features and benefits that cater to specific needs, making it essential to compare their offerings. For instance, James Hardie is a renowned name in the industry, known for its durability and moisture resistance. Their HardieBacker board is particularly popular among tile installers due to its ease of use and lightweight design.

On the other hand, DuraScore offers a more budget-friendly option without compromising quality. Its backer board is designed with a unique scoring feature, enabling quick and clean cuts, which can significantly streamline the installation process. Additionally, products like PermaBASE stand out for their versatile applications, suitable for both indoor and outdoor uses, and their exceptional resistance to mold and moisture. By thoroughly comparing these brands, you can make an informed decision that aligns with your project requirements, ensuring a successful and long-lasting installation.

Installation Tips for Fiber Cement Backer Board: Best Practices

When it comes to installing fiber cement backer board, following best practices can significantly enhance both the durability and performance of your projects. According to a report by the Fiber Cement Products Association, using appropriate installation techniques not only minimizes the risk of moisture infiltration but also helps achieve a lifespan of up to 50 years for structures. It’s crucial to start with a clean, dry surface and apply a suitable vapor barrier to prevent water damage. Proper sealing of joints using fiberglass tape and thin-set mortar can further ensure a robust installation.

In terms of tools and materials, industry guidelines emphasize the importance of using non-corrosive fasteners and a scoring knife for cutting fiber cement boards. A recent study showed that projects using corrosion-resistant screws experienced 30% fewer failures over time compared to those installed with standard fasteners. Additionally, always refer to the manufacturer's specifications for recommended installation methods, as variances in board thickness and moisture exposure can influence the overall success of the installation process. By adhering to these best practices, contractors can significantly improve the longevity and effectiveness of their fiber cement backer board projects.

The Ultimate Guide to Choosing the Right Fiber Cement Backer Board for Your Projects

This chart provides a comparison of various types of fiber cement backer boards based on their thickness, moisture resistance, and fire rating. The data helps in deciding which type suits your project requirements best.

Common Mistakes to Avoid When Using Fiber Cement Backer Board

When utilizing fiber cement backer board in construction projects, avoiding common pitfalls can significantly enhance durability and effectiveness. One prevalent mistake is improper installation. According to the Portland Cement Association, improperly installed boards can lead to moisture intrusion, which accounts for over 90% of construction-related failures. Ensuring that boards are correctly aligned, securely fastened, and sealed at joints can prevent issues down the line such as mold growth and structural damage.

Another common error is neglecting to account for weight and loading requirements. The American Concrete Institute emphasizes that different projects may require specific strength attributes from backer boards. Overloading these boards without considering their weight capacity can compromise the integrity of tiled or finished surfaces, leading to cracking or detachment. It’s vital to reference manufacturer specifications and industry standards to select the appropriate thickness and type of fiber cement board for your project’s needs, ensuring long-lasting performance and stability.

The Ultimate Guide to Choosing the Right Fiber Cement Backer Board for Your Projects - Common Mistakes to Avoid When Using Fiber Cement Backer Board

| Attribute |

Description |

Common Mistakes |

| Thickness |

Typically ranges from 1/4" to 1/2" |

Choosing the wrong thickness for your tile or substrate |

| Moisture Resistance |

Highly resistant to moisture, ideal for wet areas |

Failing to seal edges or joints properly |

| Weight |

Heavy compared to other backer boards |

Not accounting for structural support needed |

| Installation Method |

Can be installed using screws or nails |

Using the wrong fasteners that may corrode |

| Cutting |

Best cut using a score-and-snap method |

Using the wrong tools that create dust or chipping |

| Joint Treatment |

Requires fiberglass tape and thin-set mortar |

Skipping joint treatment or using inadequate materials |

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

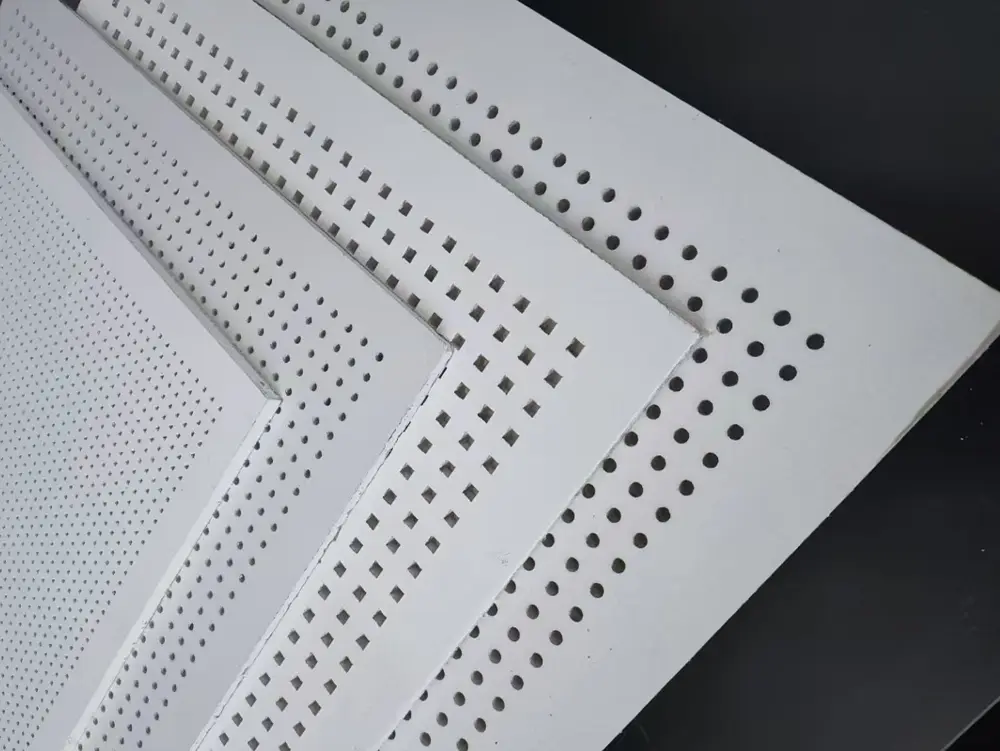

LEAO®Deco Ceiling LEAO® Perforated Ceiling

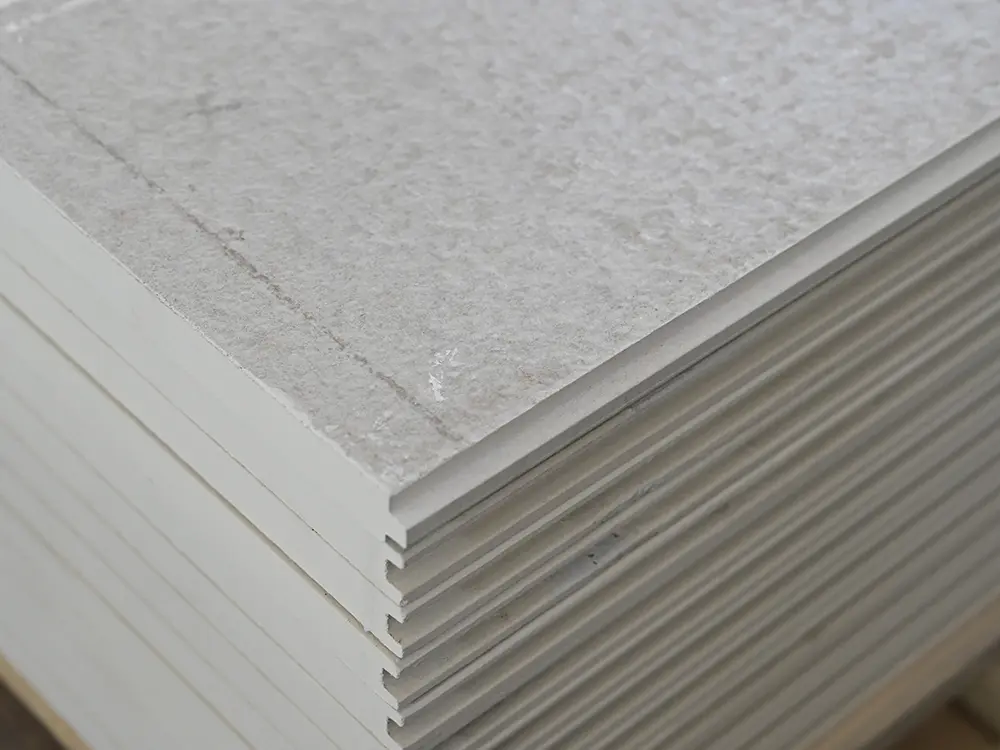

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel In the realm of

In the realm of