How to Use Fiber Cement Board for Home Building Projects?

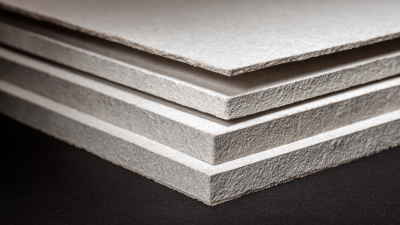

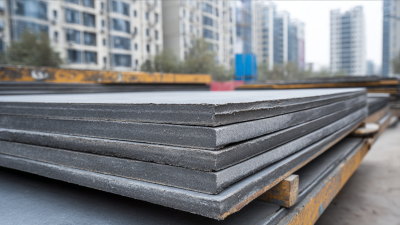

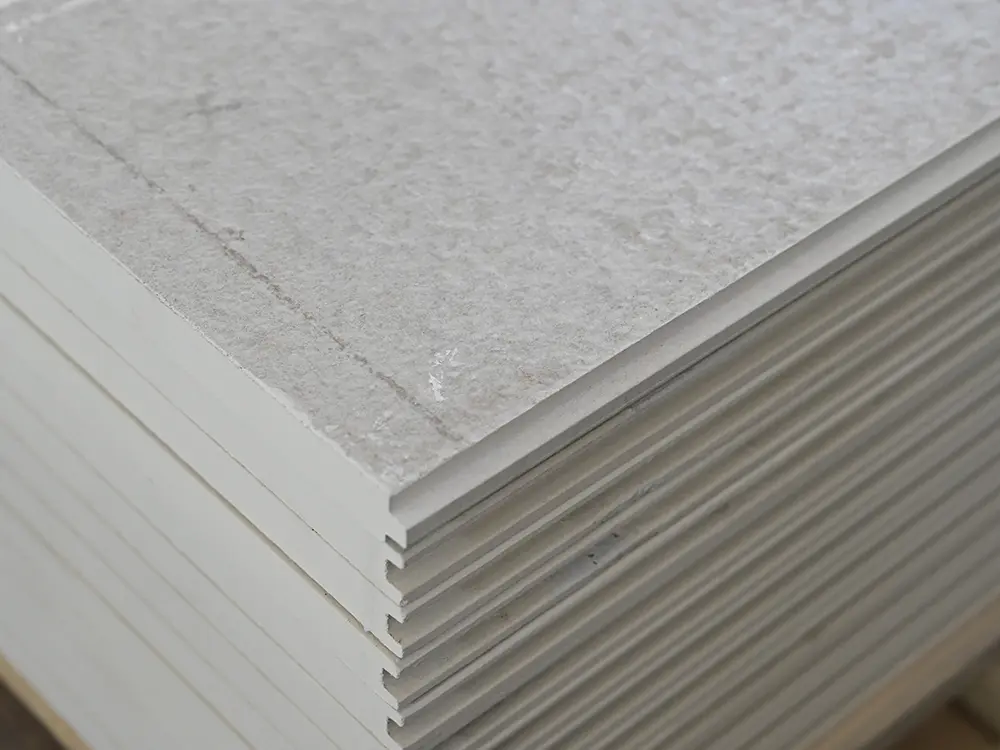

Fiber Cement Board has gained popularity in home building projects due to its durability and versatility. This material combines cement, cellulose fibers, and sand, creating a strong and resilient product. It offers excellent resistance to moisture, pests, and fire, making it an ideal choice for various applications.

When using Fiber Cement Board, it’s essential to understand its properties and installation requirements. Accurate measurements and cutting are crucial for achieving a clean finish. Pay attention to local climate conditions; they can influence the choice of materials and methods.

However, there are common challenges. Improper installation can lead to issues like warping or cracking. Learning from past mistakes ensures better results based on experience. In summary, Fiber Cement Board can enhance your building project if used correctly, but ongoing reflection on your methods is vital for success.

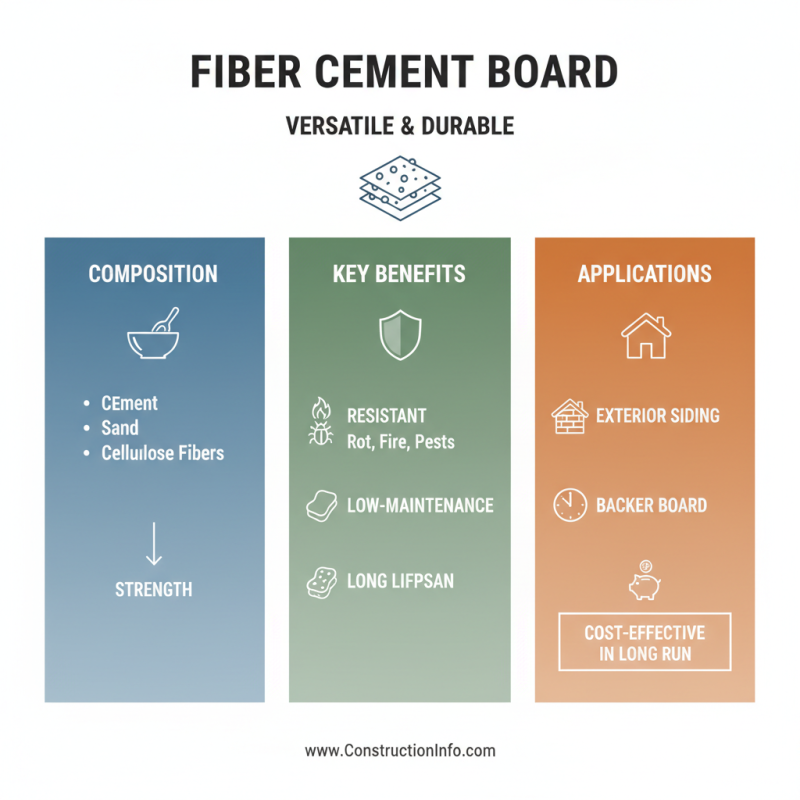

Understanding Fiber Cement Board: Composition and Benefits

Fiber cement board is a versatile material made from a mix of cement, sand, and cellulose fibers. This unique composition gives it strength and durability. It resists rot, fire, and pests, making it an excellent choice for various construction projects. Homeowners appreciate its low maintenance needs. Its long lifespan can reduce costs in the long run.

Using fiber cement board can come with some challenges. Proper installation is key to maximizing its benefits. Mistakes in cutting or fastening can lead to issues over time. It's crucial to follow guidelines closely to avoid future repairs. Consider the environmental impact as well. While fiber cement board is durable, its production requires heavy energy inputs. Reflecting on these aspects can help in making informed decisions.

Preparing Your Home for Fiber Cement Board Installation

Preparing your home for fiber cement board installation requires careful planning and attention to detail. Assess the condition of your existing exterior walls. Look for any damage, such as rot or mold, that may require repair. Fixing these issues upfront will save you time later. Ensure a clean working area, free from debris and clutter. This will help the installation process go smoothly.

You'll also want to measure your space accurately. Use a reliable measuring tape and jot down the dimensions. This will help you purchase the right amount of fiber cement board. Check your local building codes as well. Each area may have specific regulations regarding materials and installation methods. Ignoring this might lead to complications later.

Consider the weather conditions before starting your project. High humidity or heavy rain can affect the installation process. It's crucial to wait for a dry period. Having the right tools on hand is essential too. Gather items like a saw, drill, and screws. Each tool has a specific purpose in the process. Trying to improvise tools may lead to mistakes. Make sure to apply caulk around windows and doors for sealing. This step often gets overlooked but is vital for durability.

Step-by-Step Installation Process of Fiber Cement Board

Fiber cement board is a popular choice for home building projects due to its durability and weather resistance. Installing it correctly ensures a long-lasting finish. The process begins with proper preparation of the chosen area. Clear the space, ensuring it’s free from debris. Measure the area and mark where each board will go. Accurate measurements prevent waste and improve aesthetics.

Next, cut the boards to the necessary sizes using a fine-toothed saw. Wear a mask to protect against dust. Secure the boards using corrosion-resistant screws, spacing them appropriately. Ensure edges align smoothly to avoid gaps. After fastening, you might notice uneven edges. A simple sanding can help achieve a more polished look.

**Tip:** Always wear protective gear during installation. Safety is crucial when working with power tools and dust. Additionally, contemplate the climate of your location. Fiber cement boards perform well in harsh conditions, but local humidity levels can affect their lifespan. Regular maintenance checks can also help identify issues early. This proactive approach is essential for the sustainability of the installation.

How to Use Fiber Cement Board for Home Building Projects

| Step |

Description |

Materials Needed |

Estimated Time |

| 1 |

Prepare the surface where the fiber cement board will be installed. |

Leveling tools, cleaning supplies |

1 hour |

| 2 |

Cut the fiber cement board to fit the dimensions of the surface. |

Measuring tape, saw, safety goggles |

2 hours |

| 3 |

Attach the fiber cement board to the surface using screws. |

Screwdriver, screws |

1 hour |

| 4 |

Seal the seams with tape and compound. |

Joint tape, joint compound |

1 hour |

| 5 |

Finish with paint or a protective coating. |

Paint, brush or roller |

2 hours |

Finishing and Maintenance Tips for Fiber Cement Board Applications

Fiber cement board is an excellent choice for exterior applications due to its durability and weather resistance. However, proper finishing and maintenance are crucial for optimal performance. According to the Portland Cement Association, fiber cement can last over 50 years with the right care.

One essential tip is to regularly inspect the seams and joints. Look for any gaps or cracks. Filling these areas with appropriate sealants can prevent moisture intrusion. It’s advisable to paint or coat the board with high-quality exterior paint after installation, as it enhances water resistance. The American Coatings Association reports that a good finish can add years to the lifespan of fiber cement boards.

Cleaning is equally important. A simple rinse with water can remove dirt and debris. For deeper cleaning, a mild detergent is recommended. Avoid using harsh chemicals, as they can damage the board. Over time, you may notice faded areas due to sun exposure. A fresh coat of paint can rejuvenate the look and ensure continued protection.

Maintenance might seem tedious but is necessary. Regular upkeep prevents serious issues down the line. Diligent attention to your fiber cement boards can ensure they remain functional and visually appealing for decades. Keeping an eye on wear and tear helps to address problems before they escalate.

Common Mistakes to Avoid When Using Fiber Cement Board

When using fiber cement board, several common mistakes can lead to issues later on. Many DIYers underestimate the importance of proper installation. Cutting the boards incorrectly can result in gaps or uneven edges. Using the wrong tools for cutting may also lead to chipping.

People often ignore safety precautions too. Wearing protective gear is essential when working with these materials. Dust from cutting can harm your lungs.

Another mistake is neglecting to acclimate the boards before installation. Fiber cement board can expand or contract with moisture changes. Skipping this step can create problems down the line. Properly sealing joints and edges is crucial, yet many overlook this detail. Failure to seal can lead to water infiltration, causing damage.

Improper fastening is also a frequent issue. Many do not follow the manufacturer's guidelines for screw spacing and type. This can lead to boards sagging or even coming loose entirely. Ensure correct placement and use of fasteners to prevent these problems. Addressing these common errors early can save a lot of time and frustration.

Products

About Us

Download

News

Blog

Contact Us

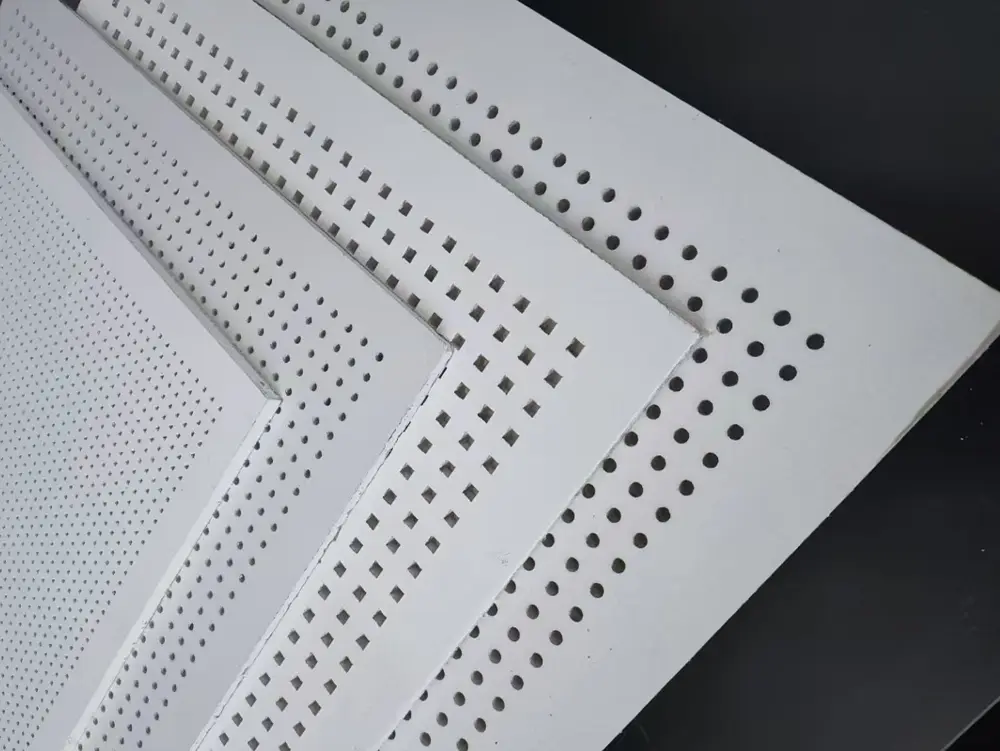

LEAO®Deco Ceiling

LEAO®Deco Ceiling LEAO® Perforated Ceiling

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel