How to Effectively Utilize Fiber Cement Backer Board for Superior Moisture Resistance and Durability

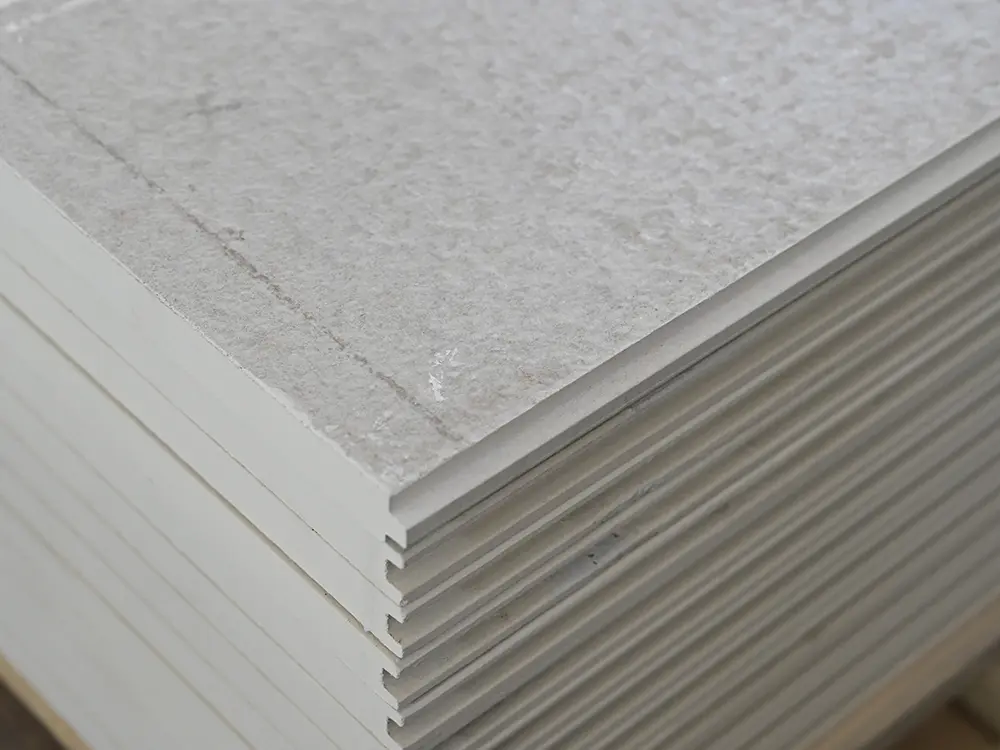

Fiber Cement Backer Board is becoming increasingly recognized in the construction and remodeling industries for its unparalleled moisture resistance and durability. According to a report by the National Association of Home Builders (NAHB), homes equipped with fiber cement materials see a significant reduction in maintenance costs, with some studies indicating up to 30% fewer repairs related to moisture damage. The use of Fiber Cement Backer Board offers excellent protection against mold, mildew, and rot, which are common issues in high-moisture areas like bathrooms and kitchens.

Fiber Cement Backer Board is becoming increasingly recognized in the construction and remodeling industries for its unparalleled moisture resistance and durability. According to a report by the National Association of Home Builders (NAHB), homes equipped with fiber cement materials see a significant reduction in maintenance costs, with some studies indicating up to 30% fewer repairs related to moisture damage. The use of Fiber Cement Backer Board offers excellent protection against mold, mildew, and rot, which are common issues in high-moisture areas like bathrooms and kitchens.

As highlighted in the 2022 Green Building Market and Impact Report, the demand for sustainable and resilient building materials, such as Fiber Cement Backer Board, continues to rise, making it a preferred choice for many contractors. By effectively utilizing this innovative material, builders can ensure long-lasting structures that meet both aesthetic and functional needs, thus enhancing property value and customer satisfaction.

Selecting the Right Fiber Cement Backer Board for Your Project

When selecting the right fiber cement backer board for your project, it's essential to understand its role in providing superior moisture resistance and durability. According to industry reports, high-quality fiber cement boards can absorb only about 5% of their weight in water, making them highly resistant to mold and rot compared to traditional substrates. This characteristic is particularly beneficial in areas prone to high humidity, such as bathrooms and kitchens.

Additionally, the choice of fiber cement board can significantly influence the longevity of your flooring installation. Research indicates that the incorporation of moisture-resistant underlayments, like those utilized with vinyl plank flooring, enhances thermal insulation and sound dampening properties while further acting as a moisture barrier. When paired with a suitable backer board, these underlayments can effectively protect your flooring from potential damage caused by leaks or spills, ultimately extending the lifespan of your investment. When making your selection, consider factors such as thickness, density, and the specific requirements of your project to ensure optimal performance.

Preparing Your Space for Optimal Fiber Cement Installation

Preparing your space for optimal fiber cement installation requires careful consideration and attention to detail. Before beginning the installation process, it is crucial to inspect the area for moisture, as fiber cement backer board excels in moisture resistance but requires a dry surface to perform optimally. Ensure that the underlying structure is free from any signs of damage or excess moisture, which can compromise the integrity of the boards. Additionally, preparing a clean and level substrate is essential to achieve proper adhesion and a seamless finish.

Furthermore, incorporating innovative construction approaches can enhance the installation process and overall efficiency. For instance, advances in materials such as self-adhesive resin cement can improve the bonding strength when used with fiber products, making the installation more durable. Ensuring adequate light-curing time during installation can also significantly affect the final mechanical properties of the materials employed. By addressing these critical preparation steps, homeowners and contractors can maximize the benefits of fiber cement backer board, ensuring a robust and moisture-resistant finish that lasts.

Step-by-Step Installation Guide for Fiber Cement Backer Board

When installing fiber cement backer board, preparation is key. Start by ensuring the surface where the board will be installed is clean and dry. Measure and cut the board accurately using a scoring tool or circular saw. For a snug fit, leave a small gap between the boards and any adjacent structures to allow for expansion.

**Tips:** Always wear safety goggles and a mask while cutting to protect yourself from dust and debris. Additionally, consider using a utility knife for smaller adjustments to ensure clean edges.

Next, secure the backer board to the framing with corrosion-resistant screws, ensuring that the screws are placed every 8 inches along the edges and every 12 inches in the field. Be mindful not to overdrive the screws, as this could compromise the board's integrity. Tape over the joints with fiberglass mesh tape and apply a thin layer of thin-set mortar to reinforce the seams.

**Tips:** It’s advisable to stagger the boards during installation to minimize potential cracking. Also, ensure that the installation is level by frequently checking with a level tool throughout the process.

How to Effectively Utilize Fiber Cement Backer Board for Superior Moisture Resistance and Durability

| Installation Step |

Description |

Tools Required |

Estimated Time |

| Preparation |

Ensure the area is clean and free of debris. |

Broom, vacuum |

30 minutes |

| Measuring |

Measure the wall and cut the backer board to fit. |

Tape measure, straight edge, marker |

1 hour |

| Cutting |

Cut the backer board using a circular saw or utility knife. |

Circular saw or utility knife, safety goggles |

1 hour |

| Installation |

Attach the backer board to the wall using screws. |

Power drill, backer board screws |

2 hours |

| Sealing Joints |

Apply seam tape and joint compound to seal joints. |

Seam tape, joint compound, trowel |

1 hour |

| Finishing |

Sand the joints and apply a waterproof finish. |

Sander, waterproof paint |

1 hour |

Essential Tools and Techniques for Waterproofing with Fiber Cement

When working with fiber cement backer board, utilizing the right tools and techniques for waterproofing is critical to enhancing moisture resistance and ensuring the durability of your project. Start with high-quality sealants and adhesives specifically formulated for use with fiber cement. These products not only provide secure bonding but also create a waterproof barrier that prevents moisture penetration. A caulking gun is an essential tool to apply sealant smoothly and precisely around edges and seams, minimizing the risk of leaks.

When working with fiber cement backer board, utilizing the right tools and techniques for waterproofing is critical to enhancing moisture resistance and ensuring the durability of your project. Start with high-quality sealants and adhesives specifically formulated for use with fiber cement. These products not only provide secure bonding but also create a waterproof barrier that prevents moisture penetration. A caulking gun is an essential tool to apply sealant smoothly and precisely around edges and seams, minimizing the risk of leaks.

In addition to adhesives, incorporating proper installation techniques is vital. Begin by ensuring that the backer board is installed with an appropriate gap between sheets to allow for expansion and drainage. Using a waterproof membrane over the board can further enhance moisture protection, especially in areas prone to water exposure, such as bathrooms or kitchens. Familiarizing yourself with the correct methods of sealing joints and transitions will greatly contribute to the longevity of the structure, making the use of fiber cement an effective choice for resilient building applications.

Maintaining Fiber Cement Backer Board for Long-Lasting Performance

To ensure that fiber cement backer board delivers long-lasting performance, regular maintenance is key. One of the essential steps is to inspect the boards periodically for any signs of moisture damage or wear. This includes checking for any cracks, chips, or other forms of deterioration that may compromise the integrity of the material. If any damage is detected, timely repairs or replacements should be made to prevent further issues.

Another crucial aspect of maintaining fiber cement backer board is proper sealing and painting. Applying a high-quality water-resistant sealant or paint can provide an additional layer of protection against moisture ingress, thereby enhancing the board's durability. It is advisable to refresh the sealant periodically, as it can wear down over time, especially in areas exposed to harsh weather conditions. Additionally, ensuring proper installation and ventilation during construction can significantly reduce moisture-related problems, contributing to the longevity of the fiber cement backer board.

Products

About Us

Download

News

Blog

Contact Us

LEAO®Deco Ceiling

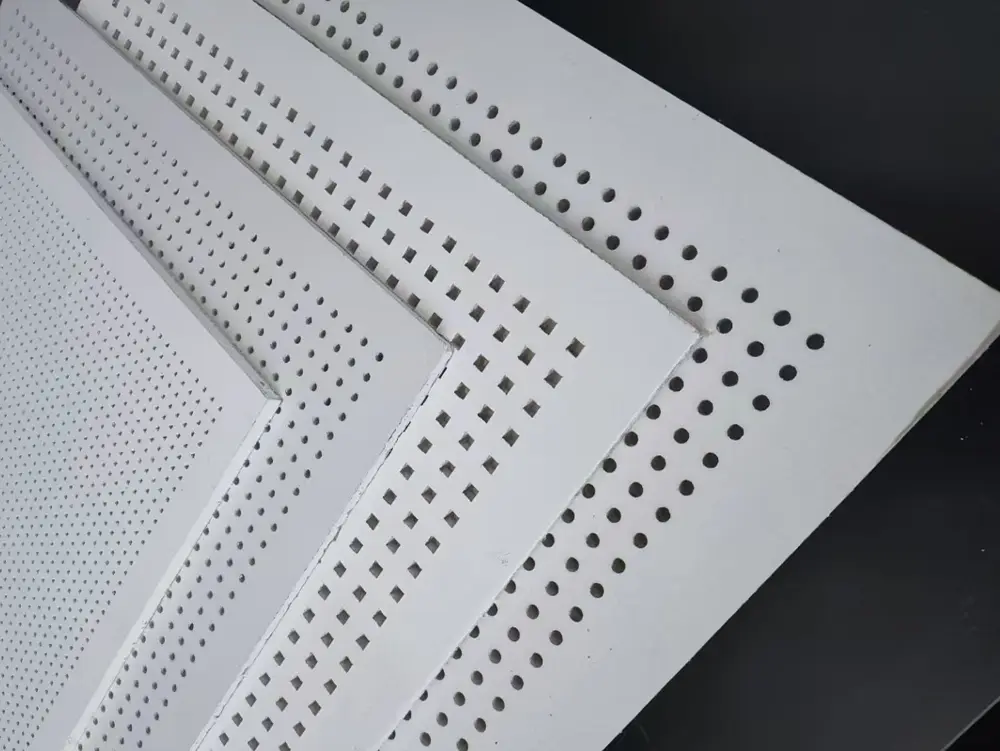

LEAO®Deco Ceiling LEAO® Perforated Ceiling

LEAO® Perforated Ceiling LEAO® Ceiling Board

LEAO® Ceiling Board LEAO® Groove Interior Panel

LEAO® Groove Interior Panel LEAO® Interior Board

LEAO® Interior Board LEAO® Wood Grain Plank

LEAO® Wood Grain Plank LEAO® Grooved Exterior Panel

LEAO® Grooved Exterior Panel LEAO® Weatherboard

LEAO® Weatherboard LEAO® Access Floors

LEAO® Access Floors LEAO® Non-removable Formwork

LEAO® Non-removable Formwork LEAO® Mezzanine Board

LEAO® Mezzanine Board LEAO® Ceramic Tile Underlay

LEAO® Ceramic Tile Underlay LEAO® Floor Plank

LEAO® Floor Plank LEAO® Flooring

LEAO® Flooring LEAO® Wood Style Decorative Panel

LEAO® Wood Style Decorative Panel LEAO® Stone Style Decorative Panel

LEAO® Stone Style Decorative Panel LEAO® Pure Style Decorative Panel

LEAO® Pure Style Decorative Panel Fiber Cement Backer Board is becoming increasingly recognized in the construction and remodeling industries for its unparalleled

Fiber Cement Backer Board is becoming increasingly recognized in the construction and remodeling industries for its unparalleled  When working with fiber cement backer board, utilizing the right tools and techniques for waterproofing is critical to enhancing moisture resistance and ensuring the durability of your project. Start with high-quality sealants and adhesives specifically formulated for use with fiber cement. These products not only provide secure bonding but also create a waterproof barrier that prevents moisture penetration. A caulking gun is an essential tool to apply sealant smoothly and precisely around edges and seams, minimizing the risk of leaks.

When working with fiber cement backer board, utilizing the right tools and techniques for waterproofing is critical to enhancing moisture resistance and ensuring the durability of your project. Start with high-quality sealants and adhesives specifically formulated for use with fiber cement. These products not only provide secure bonding but also create a waterproof barrier that prevents moisture penetration. A caulking gun is an essential tool to apply sealant smoothly and precisely around edges and seams, minimizing the risk of leaks.